What is the purpose of an oil press

Oil press is a type of oil processing machinery that extracts vegetable oil by squeezing pre treated oil. The spiral oil press used as a pre press machine is used to pre press the oil material under high pressure, and the pre pressed bad cake is then placed into the oil press machine for further pressing or oil extraction by leaching method. Therefore, the volume change of the crushing chamber at the inlet and outlet ends is significant, and the production capacity is also significant. The oil press can operate continuously, with low labor intensity. The residue cake after oil extraction is thin and small, making it easy for comprehensive utilization.

How does an oil press work?

Oil presses extract oils from seeds by mechanically squeezing them. The core principle involves using pressure to disrupt the cellular structure of the seeds, causing the oil to transfer from the solid phase (seeds) to the liquid phase (oil) for collection.

The screw oil press applies high pressure to oilseeds through a continuously rotating screw to separate oil from solids. Its core process consists of four stages: feeding, pressing, oil extraction, and residue discharge.

- Raw Material Preparation: Oilseeds (such as peanuts, rapeseed, soybeans) require pretreatment including cleaning (removing impurities), crushing (reducing particle size), steaming and roasting (for hot-pressing mode), or drying (for cold-pressing mode).

- Hot-Press Steam Roasting: High temperatures (100-130°C) soften oilseed cells, denature proteins, reduce oil viscosity, and enhance oil extraction rates.

- Cold-Press Direct Feeding: Oilseeds bypass roasting and enter the press chamber directly to preserve nutrients.

- Pressing Process

- Press Chamber Structure: Composed of a screw press (helical shaft) and a press cage (fixed sleeve), the gap between the screw press and press cage gradually narrows to create a high-pressure environment.

- Compression and Friction:

- The rotating screw press propels the oilseeds forward while the press cage restricts their radial expansion, forcing oil to separate from the cells.

- Under high pressure, the oilseeds undergo triple action—compression, shearing, and friction—causing cell walls to rupture and separating oil from solids (oil cake).

- Pressure Gradient: Chamber pressure increases progressively from inlet to outlet (reaching tens of megapascals), ensuring complete oil extraction.

- Oil Outlet: Oil flows out through the fine holes or gaps in the press cage, collected by the oil guide channel into the oil drum.

- Residue Outlet: The remaining cake residue (containing less than 5% residual oil) is discharged from the end of the press chamber and can be further processed into feed or fertilizer.

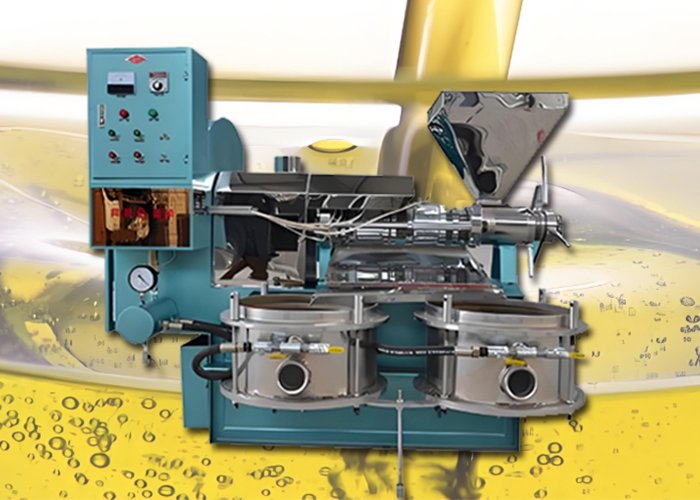

Common Types of Oil Presses

- Screw Oil Press

- The screw oil press is a fully hydraulic, automated edible oil processing machine that uses a rotating screw shaft to continuously advance the feedstock, enabling efficient, continuous oil extraction. Its core advantages lie in its compact structure, user-friendly operation, and high oil yield. Widely adopted by individual entrepreneurs, small oil mills, and large-scale oil processing facilities, it supports the pressing of over 60 types of oilseeds, including peanuts, soybeans, rapeseed, and sunflower seeds.

- Hydraulic Oil Press

- The hydraulic oil press is designed based on Pascal’s principle (a principle of hydraulics). Within a sealed container, any change in pressure at a single point in a balanced fluid transmits equal pressure in all directions. By generating substantial pressure through the hydraulic system and applying it to the oilseeds, the oil within the seeds is squeezed out.

What is the purpose of an oil press?

An oil press is a mechanical device used to extract oil from oilseeds. Its primary function is to separate oil from plant seeds, fruits, or nuts through physical or chemical methods, producing edible, industrial, or biofuel-grade oils.

- Oil Processing: Oil presses are used for large-scale production of vegetable oils such as rapeseed oil, soybean oil, and peanut oil, supplying supermarkets or the food service industry. Some equipment also features refining capabilities, enabling the production of refined oils that meet national standards.

- Industrial Raw Material Extraction: Certain plant oils (such as almond oil and jojoba oil) possess medicinal or skincare value. Oil presses can extract these oils for use as raw materials in pharmaceuticals or cosmetics.

- Biodiesel Production: Oil is extracted from crops such as rapeseed, soybeans, and palm fruits using oil presses, then converted into biodiesel through transesterification. This serves as a renewable energy source to replace fossil fuels.

- Oil Cake Utilization: The residue left after oil extraction—such as soybean meal and rapeseed meal—is rich in protein and fiber. It can be used as animal feed (for pigs, chickens, and fish) or as organic fertilizer, enabling the recycling of resources.

Oil presses serve a wide range of applications, playing a vital role in everything from daily edible oil production to industrial raw materials, biofuels, and specialty oil extraction. Selection should be based on comprehensive considerations including oilseed type, production scale, and intended use (such as whether refining is required) to achieve efficient and economical oil extraction.

Contact us to develop a complete oil processing solution for you.

Oil Press Equipment and Oil Refining Machinery for Sale – Start Your Oil Press Business

Oil Press Equipment and Oil Refining Machinery for Sale – Start Your Oil Press Business