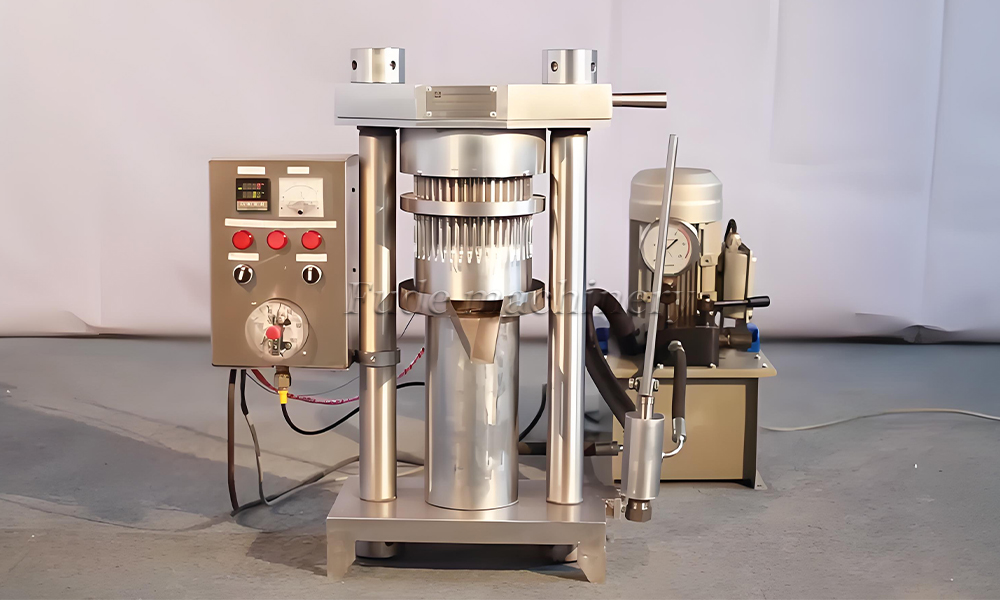

oil hydraulic press

oil press at home/oil press machine for small business

name:oil press machine industrial

Model:6yz-360

Package size:1200*1600*1680mm

Working pressure:55-60mpa

One hour production:90kg/h

power:1.5kw

Warranty period:12 months

Table of Contents

- oil press at home/oil press machine for small business

- Characteristics of plant oil press

- Working principle of rapeseed oil press

- The structural composition of rosin oil press

- The use and maintenance of sesame oil press machine

- Suggestions for purchasing small oil press

- How much oil can a soybean oil press produce per 100 kilograms

- How to turn waste into treasure from soybean residue after oil extraction

- soybean oil press machine configuration table

- Application scope of sunflower oil press machine

The pecan oil press is mainly composed of electrical control, automatic heating, adjustment, transmission, and vacuum oil filtration components. By carburizing the alloy steel, the surface hardness and wear resistance are enhanced; Squeezing and discharging are ground by a flat grinder to ensure oil line accuracy and improve oil yield.

Oil outlet

feed port

Squeezing chamber

operation box

Characteristics of plant oil press

The characteristic of pumpkin seed oil press machine is that the equipment pressure is static pressure, the mechanical friction of the oil is very small, the oil is very clear, and the oil can be directly consumed without any treatment, which is convenient and safe. This device has high-pressure and high-temperature pressure oil, and almost all oil can be pressed out of the oil. The hydraulic press has the characteristics of high efficiency, environmental protection and energy conservation, high product added value, no loss, no noise, no need for heating or adding any chemical raw materials, no need for clean oil, easy operation, no worn parts, and long service life.

Working principle of rapeseed oil press

The rosin oil heat press has two types based on the power supply of the oil pump: manual and electric; According to the pressure applied to the material, it can be divided into two types: vertical and horizontal. The base of the fully automatic hydraulic oil press is fixed with a cylinder, which is equipped with a cylindrical piston, and the upper part of the piston is connected to the cake plate as a whole. The billet is pre pressed into a circular billet, and 20-40 circular billets are stacked between the billet plate and the top plate. There are thin plates separating holes between the billets, which drive the piston at the top to generate pressure and press the billet out of oil. After pressurization, the oil pump stops pressurizing, the piston descends, the slag cake is discharged, the feed cake is reloaded, and the oil is repeatedly pressurized intermittently.

Soybean oil press

Walnut oil press

Sesame oil press

The structural composition of rosin oil press

hydraulic oil press

The sesame oil press mainly consists of two parts: hydraulic system and oil pressing system. The hydraulic system includes components such as hydraulic pumps, hydraulic valves, oil tanks, and oil pipes; The oil system includes components such as oil cylinders, pressing screws, and oil filters.

The use and maintenance of sesame oil press machine

- Pay attention to maintaining cleanliness and hygiene. Before and during pressing, it is necessary to pay attention to the cleanliness of the piston surface, and promptly clean the dirt and oil adhering to the piston surface.

- Pay attention to maintaining a reasonable pressure. When using the oil pump to pressurize, do not act too quickly or forcefully to prevent hydraulic components from being damaged by oil impact. When reducing pressure, the return valve must be opened first. When the oil in the cylinder flows back into the tank, the valve should be slowly opened to avoid a sudden drop in pressure.

- During operation and use, attention should be paid to the operating condition of the machine, and vulnerable parts (such as cups, sealing devices, steel balls, pistons, etc.) should be inspected regularly, repaired and replaced in a timely manner. Loose nuts should be tightened, and the machine should be regularly inspected and cleaned.

Suggestions for purchasing small oil press

- Select the model and specifications of the small oil press machine according to production needs and material characteristics.

- Pay attention to the quality of hydraulic oil presses and choose reliable and stable manufacturers and products.

- Pay attention to the performance and technical indicators of hydraulic oil presses, such as pressure, output, energy consumption, etc.

- Choose a hydraulic oil press that suits you, and do not blindly pursue scale to avoid

hydraulic oil press

How much oil can a soybean oil press produce per 100 kilograms

The oil content of soybeans is around 16% -20%, and the oil extraction rate of pressed soybean oil is relatively low. The oil extraction rate is about 12% -18%, which means that the oil extraction rate of soybean oil pressed with an oil press is about 12-18 pounds per hundred pounds. Squeezing soybean oil preserves the original flavor and nutrition of soybeans, so there is a high demand for the quality of soybean oil; Meanwhile, due to the high residual oil rate and low oil yield in pressed soybean cakes, the price of pressed soybean oil is relatively high.

Soybean oil

How to turn waste into treasure from soybean residue after oil extraction

The soybean residue after oil extraction can be made into nutrient rich organic fertilizer, which can reduce the generation of waste and be convenient for farmers to use. Meanwhile, due to the high content of protein in soybean residue, it can also be processed and crushed to produce foods such as soybean residue cakes and meat, which have certain economic value.

soybean oil press machine configuration table

| model | 6YZ-150 | 6YZ-180 | 6YZ-230 | 6YZ-260 | 6YZ-320 |

| Package size (mm) | 700*800*780 | 800*900*1050 | 900*1000*1400 | 1050*1100*1550 | 1120*1200*1650 |

| piston diameter (mm) | 100 | 150 | 200 | 230 | 260 |

| Barrel capacity(kg) | 2 | 4 | 8 | 12 | 17.5 |

| Youbing (Deep-fried round and flat dough-cake) diameter (mm) | 155 | 192 | 242 | 268 | 323 |

| power (kw) | 0.75 | 1.5 | 1.5 | 1.5 | 1.5 |

Application scope of sunflower oil press machine

soybean

sesame

walnut

rapeseed

Soybean oil

sesame oil

Walnut oil

rapeseed oil

Oil Press Equipment and Oil Refining Machinery for Sale – Start Your Oil Press Business

Oil Press Equipment and Oil Refining Machinery for Sale – Start Your Oil Press Business