avocado oil press machine

Double coconut oil press machine

The copra oil press is mainly used as an oil press for individual home processing. This product belongs to a type of hydraulic fully automatic oil press, with a small output but simple and convenient. The main product now is the screw oil press. There are also spiral oil presses for cold pressing, which are relatively inexpensive but have a low oil yield.

Table of Contents

- Double coconut oil press machine

- Working video of canola oil press machine

- Why is it called a citrus oil press?

- flax oil press technical parameters

- flaxseed oil press details are thoughtful and unique

- Working principle of almond oil press

- What are the advantages ofgrape seed oil press?

- hazelnut oil press machine can extract oil crops reference chart

- Good physical pressing effect and natural nutrition

- Customer cooperation cases

- Factory loading and departure site

- What is the process flow of rapeseed oil press?

Working video of canola oil press machine

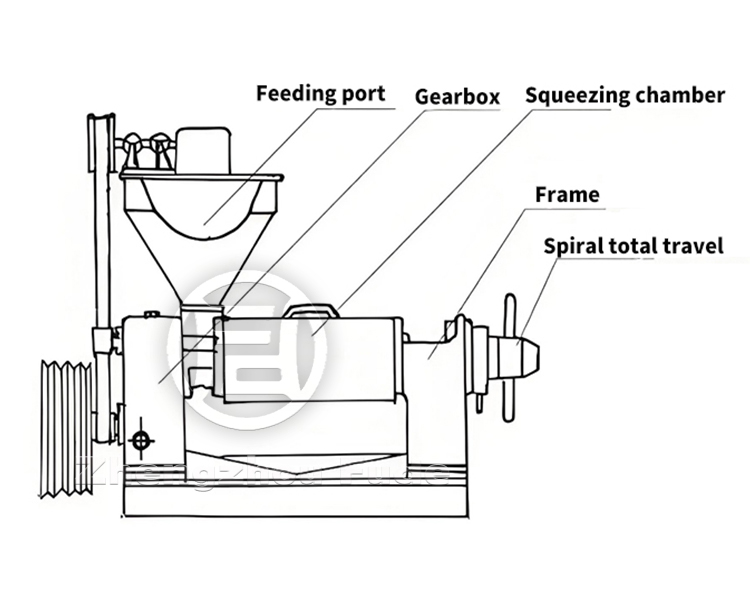

The oil extraction principle of castor oil press machine mainly utilizes the oil extraction screw rotating in the pressing chamber to squeeze out the oil material. After adding the oil material in the inlet, the screw rotates to push the oil material into the pressing chamber, which gradually deforms the oil material and separates it from the oil material through strong pressure. Meanwhile, the pressed oil residue is discharged out of the machine through the oil residue outlet and stored in the waste residue storage box.

Why is it called a citrus oil press?

The cotton seed oil press is based on the design principle of the oil press: there is a spiral shaft inside the oil press, which generates pressure through the rotation of the screw, forcing the raw material molecules to rupture, thereby achieving the purpose of oil extraction. So this type of oil press with a spiral shaft is called a spiral oil press. Spiral oil press is a common oil pressing equipment widely used in industries such as food, chemical, and pharmaceutical. It obtains oil by squeezing materials, which has the advantages of simple operation, low cost, and high oil content.

Single machine oil press

Oil press equipped with filter barrels

flax oil press technical parameters

| Oil press model | 60 type | 70 type | 80 type | 100 type | 125 type | 150 type |

| Squeezing chamber diameter | 55mm | 65mm | 80mm | 101mm | 125mm | 150mm |

| Squeezing screw speed | 52r/min | 48r/min | 47r/min | 38r/min | 36r/min | 35r/min |

| Squeezing screw speed | 2.2kw | 3kw | 5.5kw | 7.5kw | 15kw | 18.5kw |

| Processing capacity | 30-60kg/h | 50-80kg/h | 65-130kg/h | 140-280kg/h | 300-400kg/h | 500-600kg/h |

| Overall weight | 220kg | 280kg | 780kg | 1100kg | 1280kg | 1420kg |

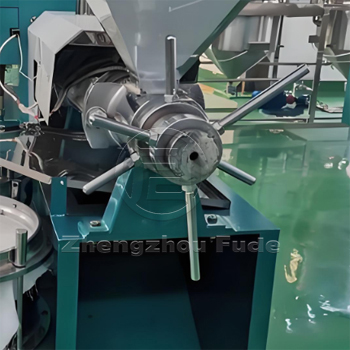

flaxseed oil press details are thoughtful and unique

- Double spiral reliable locking machine chamber

- The feeding port is widened and enlarged, making it easy to feed

- The overall framework is made of steel material, ensuring high and mild working performance

Double helix

Increase the feeding port

Steel frame

Working principle of almond oil press

The working principle of a food oil press is mainly based on the rotation of the screw shaft, which achieves the extraction of oil by continuously pushing and squeezing the material embryo in the pressing chamber. Specifically, the processed oil enters the pressing chamber from the hopper and is pushed forward by the rotating spiral shaft to move the material embryo forward. In the squeezing chamber, the material embryo is subjected to pressure and friction. As the root diameter of the squeezing screw gradually thickens and the pitch gradually decreases, the volume of the squeezing chamber space continuously shrinks, thereby exerting a squeezing effect on the material embryo. This continuous pushing and squeezing process causes the oil to be squeezed out of the material embryo and flow out through the gaps in the pressing chamber.

Spiral rod

Oil filter barrel

Filter element

What are the advantages ofgrape seed oil press?

grape seed oil press machine has a small footprint, high production efficiency, and advantages such as carefully selected materials, reasonable structure, beautiful appearance, reliable quality, simple operation, labor and electricity saving. It also has the advantages of automatic temperature control, one-time pressing, high oil yield, vacuum filtration, and high production efficiency.

Oil press structure

hazelnut oil press machine can extract oil crops reference chart

It can easily press various materials such as olives, palm fruits, flaxseeds, coconuts, peanuts, sesame, corn germ, avocado, etc. For more materials, please consult customer service

Olive

Coconut

Flaxseed

Sesame

Palm fruit

Avocado

Peanut

Sunflower seeds

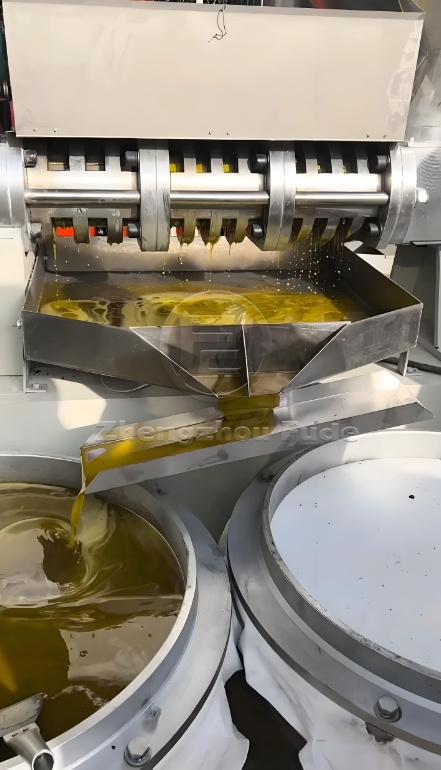

Good physical pressing effect and natural nutrition

The raw material nutrition is preserved intact, the taste is fragrant and not greasy, and it is suitable for commercial use. There are no chemical additives, ensuring the safety, hygiene, and pollution-free of the product. It is natural and nutritious, with a refreshing and pure taste.

Avocado oil

Sunflower oil

Olive oil

Sesame oil

Coconut oil

palm oil

peanut oil

Flaxseed oil

Customer cooperation cases

We have consulted and followed up with clients in the United States, the United Kingdom, South Korea, India, and other countries regarding the squeezing effect of different materials, and they have provided satisfactory answers.

American customer presses sesame oil

UK customer presses sunflower seed oil

Korean customers squeeze olive oil

Indian customers squeeze palm oil

Factory loading and departure site

What is the process flow of rapeseed oil press?

1.Put fresh palm fruit bundles into the fermentation and sterilization vehicle, and directly inject steam for high-temperature short-term fermentation and sterilization. Steam flows through the fruit chamber to heat all fruits, reducing the activity of bacteria and enzymes, avoiding the increase of free fatty acids, and improving the quality of crude oil.

2.Feed the fermented brown fruit bundle into a drum separator, and separate the empty fruit chamber from the fresh brown fruit through the rotation of the separator. Send the separated empty fruit chamber as fertilizer to be crushed and returned to the orchard.

3.Palm fruits are subjected to special equipment for tempering and crushing, and then sent to a twin-screw oil press to extract oil. Then, the liquid portion containing mud, water, and oil is sent to the purifier to separate crude palm oil.

4.The solid part of the pumpkin seed oil press machine is fed into the dynamic vertical separation column by a conveyor belt, and the fibers are separated from the fruit core using wind power.

5.The fibers are fed into the boiler as fuel.

6.Transfer the polished fruit core to a container for storing kernels, crush them, and separate the kernels. The processed palm oil mainly contains solid sediment, water, and oil. Among them, the solid part is separated through a vibrating rotary screen, and crude palm oil is decomposed using a static method. The heated crude palm oil is pumped into a vacuum dryer to remove water, and finally sent to a crude oil tank for storage. After treatment, the sediment is discharged into the sewage treatment channel, and the solid matter is used for field fertilization and steam.

7.Steam boilers are mainly used to provide steam for power generation, fermentation, sterilization, and heating. The fuel used in the steam boiler is fibers and fruit shells separated from the palm oil manufacturing process.

Oil Press Equipment and Oil Refining Machinery for Sale – Start Your Oil Press Business

Oil Press Equipment and Oil Refining Machinery for Sale – Start Your Oil Press Business