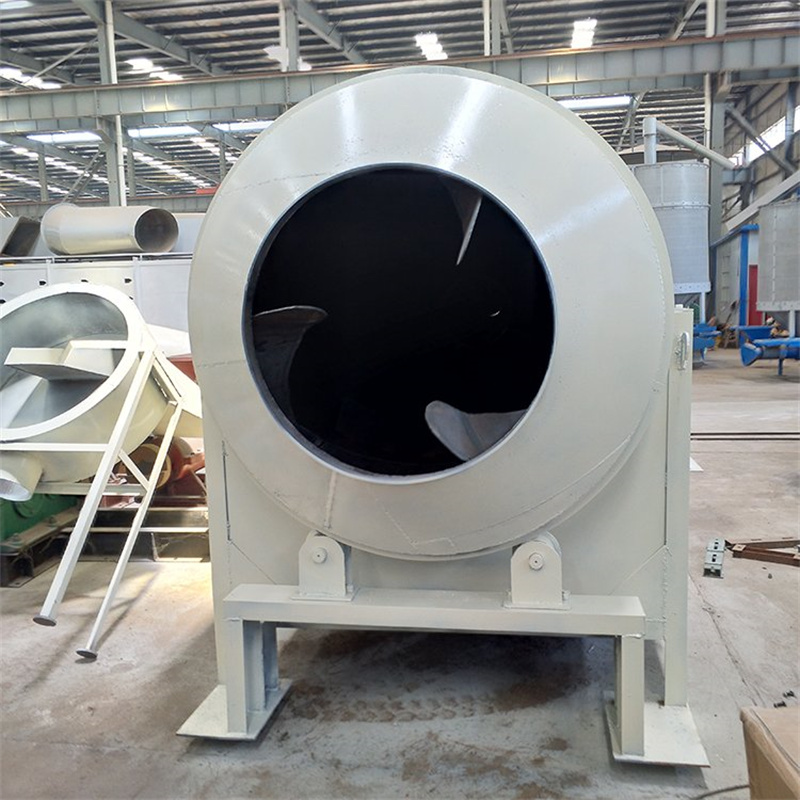

Organic fertilizer drum dryer

What is an organic fertilizer drum dryer

Organic fertilizer dryer is mainly used to dry granular materials within a certain humidity range, suitable for areas with developed large, medium, and small animal husbandry industries. According to the requirements of drying products, different heat sources can be used.

Table of Contents

- What is an organic fertilizer drum dryer

- The structure of organic fertilizer drum dryer

- The working principle of organic fertilizer drum dryer

- Scope of application of organic fertilizer drum dryer

- The effectiveness of using a organic fertilizer drum dryer

- The advantages of organic fertilizer drum dryer

- Which countries have chosen our organic fertilizer drum dryer

- Diversified display of drying machines

The structure of organic fertilizer drum dryer

The organic fertilizer dryer mainly consists of a heat source, a feeding machine, a feeding machine, a rotary drum, a material crushing device, a discharge machine, an induced draft fan, a unloader, and a distribution cabinet.

The working principle of organic fertilizer drum dryer

After dehydration, the wet material is added to the dryer, and under the flipping of the uniformly distributed plate reader in the drum, the material is evenly dispersed in the dryer and fully contacts with hot air, accelerating heat and mass transfer during drying. During the drying process, the material is discharged from another section of the star shaped discharge valve of the dryer under the action of the inclined plate and the hot air.

Scope of application of organic fertilizer drum dryer

- Chemical industry: ammonium sulfate, alkali sulfide, Anfu powder, ammonium nitrate, urea, oxalic acid, potassium dichromate, polyvinyl chloride, nitrate phosphate fertilizer, calcium magnesium phosphate fertilizer, and composite fertilizer.

- Food industry: Vitamin malt extract, granular strong sugar.

- Mineral products: manganese ore, pyrite, limestone, peat.

- Other: feed, iron powder, flat soybeans, garbage abrasives, matchsticks, sawdust, distiller’s grains.

The effectiveness of using a organic fertilizer drum dryer

The organic fertilizer drum dryer is mainly used to dry granular materials within a certain humidity range, such as yellow sand used in the dry powder mortar industry and various specifications of molding sand used in the casting industry. Blast furnace slag used in the building materials and cement industry. Small particle clay, used in the chemical industry for small particle materials that do not undergo chemical changes, are not afraid of high temperature and smoke pollution. According to the moisture requirements of different industries for dried materials, the moisture content of the dried materials can reach below 1-0.5%.

The advantages of organic fertilizer drum dryer

- The rotary dryer has a high degree of mechanization, a large production capacity, and can operate continuously.

- Excellent structure, simple production process: This machine dries fresh manure with a moisture content of 65% through high-temperature drying, disinfection and sterilization, decomposition and other processes to produce pure manure organic fertilizer with a moisture content of less than 13%,

- Less malfunctions, low maintenance costs, and low power consumption; Wide application range, good uniformity of product drying; Drying can also achieve the purpose of sterilization and deodorization.

Which countries have chosen our organic fertilizer drum dryer

Our drum dryers are sold to Southeast Asia, Europe, America, and other regions, and have received widespread praise.

Diversified display of drying machines

- The drum dryer is one of the traditional drying equipment, with reliable operation, high flexibility, strong adaptability, and large processing capacity. It is widely used in metallurgy, building materials, chemical industry, coal washing, fertilizer, ore, sand, clay, kaolin, sugar and other fields.

- A three cylinder dryer is a type of dryer that shortens the external dimensions of the dryer body by replacing the single cylinder body with three stacked cylinders. When the machine is in operation, materials and hot air flow enter the inner to outer cylinder in sequence. After the Z-shaped reciprocating flow of the machine body, the heat energy is fully utilized to dry the materials before unloading.

- The full name of a box dryer is a box type fruit and vegetable dryer. This equipment dries evenly, with fast speed and high efficiency, and the materials are not easy to stick. It can achieve automatic temperature control and moisture removal, which can keep the dried materials in a better shape, maintain the color and shape of the dried materials, and improve product quality.

Oil Press Equipment and Oil Refining Machinery for Sale – Start Your Oil Press Business

Oil Press Equipment and Oil Refining Machinery for Sale – Start Your Oil Press Business