grain dryer platte sd

What is grain dryer clubroot acres

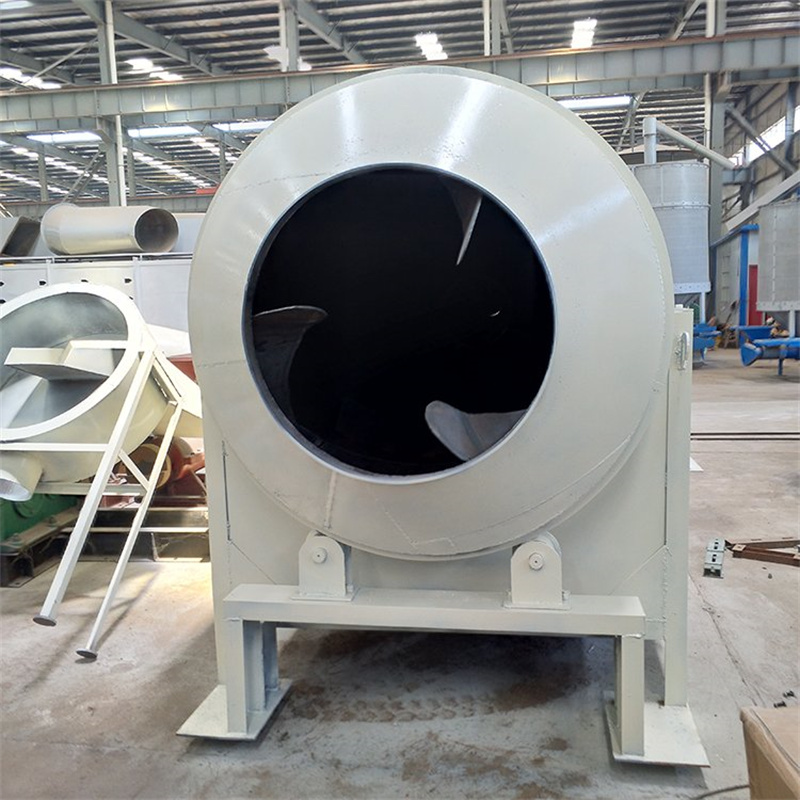

The grain drum dryer is a type of drum dryer. The pharmaceutical residue dryer has a place in the industrial drying equipment market due to its strong production capacity, large processing output, wide range of use, and convenient operation, and is loved by industry professionals.

Table of Contents

- What is grain dryer clubroot acres

- The characteristics of the drum dryer for pharmaceutical residue

- The working principle of the drum dryer for pharmaceutical residue

- Applicable materials for the gas grain dryers

- The effectiveness of the flagro grain dryer for pharmaceutical residue

- The advantages of a brewer’s grain dryer for pharmaceutical residue

- Which countries choose our medicine residue drum dryer

- Diversified display of arg grain dryers

The characteristics of the drum dryer for pharmaceutical residue

- The drum dryer is the main place for hot air heat and mass transfer of wet slag. However, in order to complete the entire drying operation, in addition to the medicine slag dryer, it is also necessary to customize the feeding device, dust removal equipment, heating equipment, etc. of the dryer according to user requirements.

- The working process of the medicine residue dryer is to break the wet residue into dispersed shapes, and then roll and lift it under the action of the plagiarism plate, greatly increasing the heating area of the material, thereby completing the water evaporation process in the wet material. After drying, the material is discharged through a conveyor belt from the discharge end.

- The medicine residue dryer has the advantages of simple structure, convenient operation, easy maintenance and management, and is widely used in many industries and fields.

The working principle of the drum dryer for pharmaceutical residue

The medicine residue drum dryer is mainly used to dry granular materials within a certain humidity range, such as yellow sand used in the dry powder mortar industry and various specifications of molding sand used in the casting industry. Blast furnace slag is used in the construction materials and cement industry. Small particle clay is a small particle material used in the chemical industry that does not undergo chemical changes and is not afraid of high temperature and smoke pollution. According to the moisture requirements of different industries for drying materials, the moisture content of drying materials can reach below 1-0.5%.

Applicable materials for the gas grain dryers

- Chemical, mining, metallurgy and other industries, such as ore, slag, coal, metal powder, clay, diatomaceous earth, kaolin.

- Agriculture, feed, and fertilizer industries, such as straw, grass, leaves, fish meal, corn sauce, starch residue, distiller’s grains, medicinal residue, fruit residue, soy sauce residue, sugarcane residue, peat, organic compound fertilizer, sludge, aquatic product waste, food factory waste, slaughterhouse waste, organic fertilizer, inorganic fertilizer, and ammonium phosphate fertilizer.

- Dry powdered and granular materials with special requirements. Such as various crystals, lightweight calcium carbonate, activated clay, magnetic powder, graphite, inorganic mud, clay, lime slurry, ore mud, phosphorus slag, aluminum plant red mud.

- Materials that require low-temperature drying and require continuous drying in large quantities.

The effectiveness of the flagro grain dryer for pharmaceutical residue

The grain drum dryer is mainly used to dry granular materials within a certain humidity range, such as traditional Chinese medicine slag used in the field of traditional Chinese medicine and various specifications of molding sand used in the casting industry. Blast furnace slag used in the building materials and cement industry. Small particle clay, a small particle material used in the chemical industry, does not undergo chemical changes and is not afraid of high temperature and smoke pollution. According to the moisture requirements of different industries for drying materials, the moisture content of the dried materials can reach below 1-0.5%.

The advantages of a brewer’s grain dryer for pharmaceutical residue

- Compact structure with small footprint. From the equipment structure of the medicine residue dryer, it can be seen that the main body is composed of three layers of concentric cylinders with different circles nested together. After wet materials and hot air enter the dryer, they can be divided into three drying stages. The heat transfer area and drying stroke are greatly increased, saving land area and infrastructure investment.

- High thermal energy utilization rate. The medicine residue dryer can adopt a direct heating method, where the medicine residue comes into direct contact with high-temperature hot air. The wet medicine residue entering the dryer gradually becomes scattered material under the joint action of the dispersing device and the lifting plate, enhancing the heat and mass transfer effect.

- Suitable for drying materials with different moisture contents. The pharmaceutical residue dryer manufacturer will design and configure the equipment reasonably based on the characteristics of the materials and drying conditions, in order to adapt to the requirements of moisture content of materials with different characteristics.

Which countries choose our medicine residue drum dryer

Our medicine residue drum dryers are sold to Southeast Asia, Europe, America, and other regions, and have received widespread praise.

Diversified display of arg grain dryers

- The allmet grain dryers is one of the traditional drying equipment, with reliable operation, high flexibility, strong adaptability, and large processing capacity. It is widely used in metallurgy, building materials, chemical industry, coal washing, fertilizer, ore, sand, clay, kaolin, sugar and other fields.

- A three cylinder dryer is a type of dryer that shortens the external dimensions of the dryer body by replacing the single cylinder body with three stacked cylinders. When the machine is in operation, materials and hot air flow enter the inner to outer cylinder in sequence. After the Z-shaped reciprocating flow of the machine body, the heat energy is fully utilized to dry the materials before unloading.

- The full name of a box dryer is a box type fruit and vegetable dryer. This equipment dries evenly, with fast speed and high efficiency, and the materials are not easy to stick. It can achieve automatic temperature control and moisture removal, which can keep the dried materials in a better shape, maintain the color and shape of the dried materials, and improve product quality.

Oil Press Equipment and Oil Refining Machinery for Sale – Start Your Oil Press Business

Oil Press Equipment and Oil Refining Machinery for Sale – Start Your Oil Press Business