How to make oil easily with a small oil press?

Tired of store-bought oils with unknown origins? Want fresher, healthier oil in your kitchen or small business? There’s a simple way to take control.

Yes, making your own edible oil is surprisingly easy using a small oil press. You choose the seeds, press them fresh, and get pure, high-quality oil. It puts you in charge of what you consume or sell.

Why Use a Small Oil Press for Homemade Edible Oil? Fresh, Healthy, and Cost-Effective?

Using a small oil press gives you incredibly fresh oil, free from preservatives or chemical residues. You control the source material, ensuring better health benefits. It can also be cost-effective, especially for organic or specialty oils.

Making your own oil opens up a world of benefits. You get oil at its peak freshness, often with more vibrant flavor and aroma than store-bought options. Health-wise, you avoid potential contaminants from industrial processing and retain more natural nutrients. This control is invaluable. For small businesses, like boutique restaurants or local food producers, offering freshly pressed oil can be a unique selling point. While the initial machine cost is a factor, pressing your own oil, particularly from readily available seeds or nuts, can lead to long-term savings compared to buying expensive cold-pressed or organic varieties. It also reduces packaging waste.

These factors make small-scale oil pressing an attractive option for both home users and small enterprises seeking quality and control.

Which Oil Seeds Are Best for Easy Oil Pressing?

Wondering which seeds give the best results with minimal fuss? Want high oil yields without complex steps? Choosing the right seed is key for easy pressing.

Peanuts, sesame seeds, sunflower seeds, rapeseed (canola), and flaxseeds are generally easy to press in small oil presses. They have good oil content and usually require simple preparation, making them ideal for beginners or quick batches.

Selecting the right seeds is crucial for a smooth oil pressing experience, especially with smaller machines. Ease of pressing often relates to the seed’s oil content, hardness, and whether the shell needs removing. Softer seeds with high oil content are typically the easiest. Harder seeds or those with very low oil content might require more robust machines or specific pre-treatment. For users of our typical screw oil presses, many common seeds work well.

For home or small-scale use, starting with peanuts, sesame, or sunflower seeds is often recommended due to their accessibility and ease of pressing. As you gain experience, you can explore other varieties.

How to Use a Small Oil Press for Edible Oil?

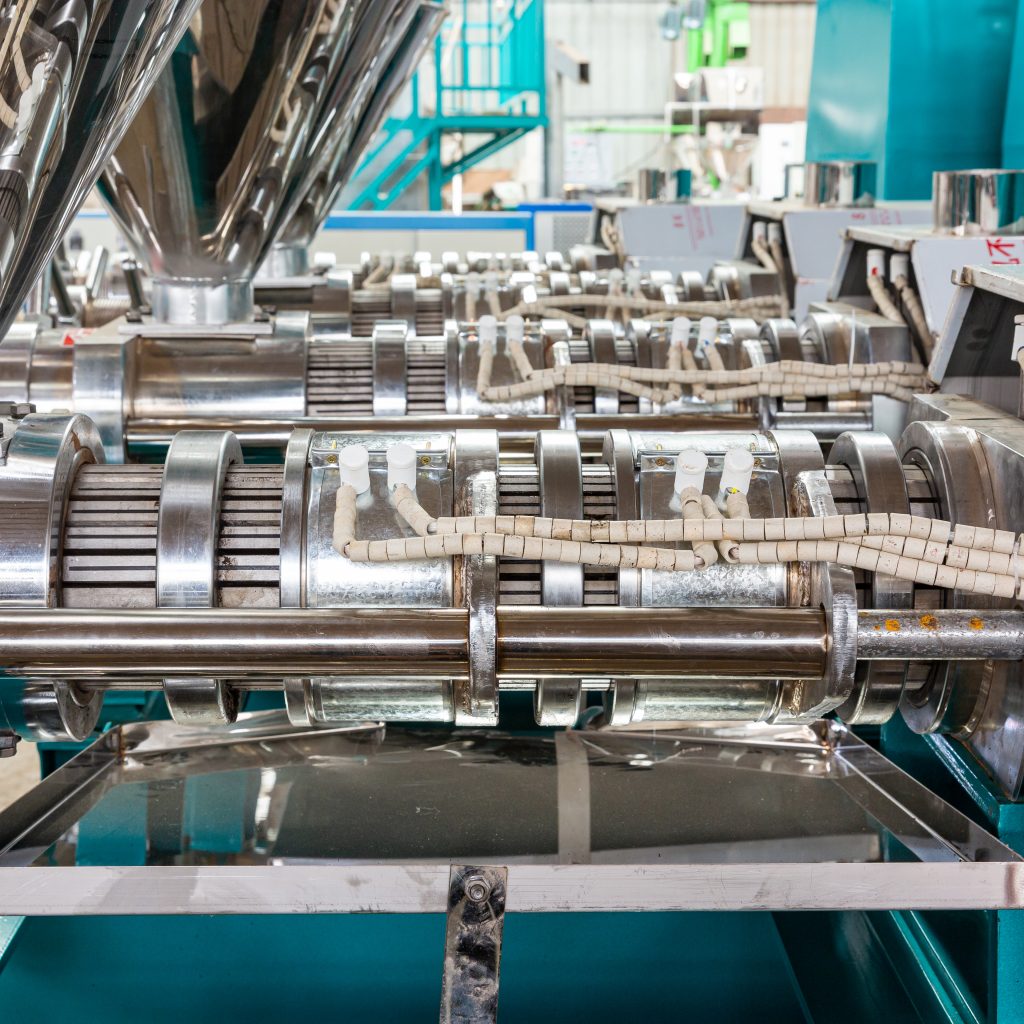

Operating a small oil press is straightforward. Generally, you prepare the seeds, preheat the machine, slowly feed the seeds into the hopper, and collect the fresh oil and byproduct (press cake).

Most modern small oil presses, especially electric screw presses designed for home or small business use, are built for user-friendliness. While specific instructions vary by model, the core process remains consistent. Safety is important – always follow the manufacturer’s guidelines, keep hands clear of moving parts, and operate on a stable surface. Our machines at Zhengzhou Fude Machinery are designed with ease of use and safety in mind, even for beginners. The goal is to make fresh oil accessible.

This process makes obtaining fresh oil achievable within minutes in your own kitchen or workshop.

Do Seeds Need Special Treatment Before Pressing? How to Simply Boost Oil Yield?

Yes, some pre-treatment often helps. Cleaning seeds is essential. Drying them to the correct moisture level (usually 5-10%) is crucial. Sometimes, gentle roasting or cracking/shelling can increase oil yield and improve flavor.

Proper seed preparation is key to maximizing the efficiency of your small oil press and the quality of your oil. Skipping these steps can lead to lower yields, difficulty pressing, or even machine damage. While some seeds press well with minimal prep, others benefit significantly from a bit more attention. For larger operations, specialized pre-treatment equipment handles these steps efficiently, but simple methods work well for small scale.

Simple Pre-Treatment Techniques

Consider these common steps:

| Pre-Treatment Step | Impact on Yield | Impact on Quality | Common Seeds Benefiting |

|---|---|---|---|

| Cleaning | Indirect (prevents jams) | High (removes contaminants) | All Seeds |

| Drying (Correct MC) | High (optimal extraction) | Good (prevents mold/spoilage) | All Seeds |

| Dehulling | High (reduces non-oil mass) | Variable (can reduce fiber) | Sunflower, Peanuts, Cottonseed |

| Roasting/Heating | Medium-High | Flavor enhancement | Sesame, Peanuts, Rapeseed |

Even simple cleaning and drying make a noticeable difference in home or small-scale oil pressing.

Can Freshly Pressed “Crude Oil” Be Eaten Directly? What Are Simple Home Filtering Methods?

Yes, the freshly pressed oil, often called “crude oil,” is generally edible but contains fine seed particles making it cloudy. Letting it settle and then carefully pouring off the clear oil, or filtering through cheesecloth or coffee filters, removes most sediment.

The oil that comes directly out of your small oil press is pure and natural but includes microscopic solids from the seed material. While safe to consume, this sediment can settle over time, potentially affect flavor stability, and shorten shelf life. Simple clarification methods enhance the oil’s appearance and usability. For commercial production, more advanced filter presses or even full refining equipment are used, but simple techniques work well at home.

Filtering not only improves appearance but helps the oil last longer by removing material that can accelerate oxidation or spoilage. Store your clarified oil in dark, airtight bottles in a cool place.

Is Cleaning a Small Oil Press Difficult After Use? Efficient Cleaning and Maintenance Tips Shared?

Cleaning a small oil press is crucial but usually simple. Run dry material (like bread crusts or dry rice) through to push out residue, then disassemble easily accessible parts (like the press screw and barrel) and wipe them clean. Regular maintenance is straightforward.

Proper cleaning and maintenance are essential for ensuring your oil press operates efficiently, produces clean oil, and lasts a long time. Neglecting cleaning can lead to buildup, blockages, unpleasant flavors transferring to new batches, and increased wear on components. Thankfully, most small presses are designed for relatively easy cleaning. Consistent care is far less daunting than tackling a heavily soiled machine. As manufacturers, we emphasize designing machines like our screw oil presses for ease of maintenance.

Consistent, simple cleaning after each use is the best way to maintain your small oil press.

Compared to Supermarket Oil, What Are the Real Cost and Health Advantages of Homemade Oil?

Homemade oil from a small oil press offers superior freshness, no additives, and full control over seed quality, which are significant health advantages. Cost-wise, it depends on seed prices and usage volume; it’s often cheaper for organic/specialty oils but might be comparable for basic oils.

Deciding whether to invest in a small oil press involves weighing the costs against the benefits, particularly concerning health and quality. Supermarket oils offer convenience and often lower upfront cost for standard varieties. However, they may involve industrial processing methods (like chemical extraction or high-heat refining) that can strip nutrients or leave residues. Homemade oil provides transparency and maximizes potential health benefits. For businesses using oil, like small food producers or restaurants, the quality difference and “fresh-pressed” appeal can justify the investment in oil extraction equipment.

Conclusion: For basic, high-volume oils, supermarket prices might be hard to beat purely on cost unless sourcing seeds very cheaply. However, for users prioritizing health, freshness, control, or needing specialty/organic oils, home pressing with a small oil press often provides superior value and significant health advantages. For small businesses, the quality differentiation can be a strong market advantage.

Related recommendations

-

Analysis of raw materials for oil press processing

40Which crops and seeds can be used for oil extraction?Determination of raw materials for oil processingWhat are the main classifications of common oil materials?Classifying by Source PartClassifying by Oil ContentCharacteristics and oil yield of di...

View details -

What is the difference between a hot press oil press and a cold press oil press

487Spiral oil presses are divided into cold press spiral oil presses and hot press spiral oil presses according to the oil pressing process, which can meet the diverse needs of users. Users can choose the appropriate oil press according to their actu...

View details -

Difference between hydraulic press and screw press

29How Do Their Working Principles Fundamentally Differ?Hydraulic Press: The Slow StrongmanScrew Press: The Continuous WorkerWhat Raw Materials Does Each Press Handle Best?Hydraulic Press Specialties:Screw Press Mainstays:How Do They Compare on Oil Y...

View details -

How to buy screw oil press

20What is a screw oil press? How is it different from other oil presses?How does a screw oil press squeeze oil out of raw materials?Pressure Build-up in the BarrelOil Separation and Cake DischargeCold press and hot press screw oil presses, which is ...

View details

Oil Press Equipment and Oil Refining Machinery for Sale – Start Your Oil Press Business

Oil Press Equipment and Oil Refining Machinery for Sale – Start Your Oil Press Business

HelloPlease log in