How to buy oil press machine to start an oil press plant?

An edible oil press machine is equipment designed to mechanically squeeze oil out of oil-bearing materials like peanuts, soybeans, or sunflower seeds. It can be profitable with good planning and the right market.

An edible oil press machine is the core of any oil extraction business. Its main job is simple: apply pressure to oilseeds or nuts to separate the oil from the solid meal. This process can be done using different technologies, which we will discuss later. The goal is to get the maximum amount of high-quality oil.

Starting an oil mill, even a small one, requires careful planning. You need to research your local market, find reliable suppliers for raw materials, and choose the right equipment for your scale and budget. With our experience since 2005 and exports to over 120 countries, we can help you make informed decisions.

What are the common types of oil press machines on the market, and what are their pros and cons?

The most common types are screw presses and hydraulic presses. Screw presses use a rotating worm shaft for continuous pressing, while hydraulic presses use static pressure from a piston.

Choosing the right type of oil press machine is crucial. Each type works differently and is suited for different situations. At Zhengzhou Fude Machinery, we manufacture both main types, offering single screw, double screw, and hydraulic options.

Screw Oil Press Machines

These are very popular for many oilseeds. A screw shaft (worm) rotates inside a barrel (press cage). Material is fed in, and the decreasing space along the rotating screw builds immense pressure, squeezing the oil out through small openings in the cage. The solid cake exits at the end.

Hydraulic Oil Press Machines

These use a hydraulic pump to drive a piston, which applies high pressure vertically onto the oilseeds packed inside a cylinder. The oil is squeezed out through holes in the cylinder base. This method often involves less friction and heat, making it suitable for “cold pressing” certain oils to preserve flavor and nutrients.

Understanding these differences helps you start thinking about which type aligns better with your production goals and the specific oilseeds you plan to process.

Screw press or hydraulic press: which one is better suited for my needs?

Choose a screw press for continuous operation, higher volume processing, and versatility with common seeds like soybean or sunflower. Opt for a hydraulic press for batch processing, specific high-value seeds like sesame or walnut, or cold pressing.

Which oil press is best for my specific oilseed (peanut/soybean/rapeseed/sunflower, etc.)?

Most common seeds like peanut, soybean, rapeseed, and sunflower work well in screw presses, especially temperature-controlled ones for optimal yield. Hydraulic presses are excellent for seeds like sesame, walnut, or when cold pressing is desired.

Different oilseeds have unique characteristics – size, hardness, oil content, shell presence. Choosing the right oil press machine ensures efficient extraction. At Zhengzhou Fude Machinery, our customization capability means we can advise on and provide the best fit.

Seed-Specific Considerations:

- Peanuts (Groundnuts):

- Best Press: Screw oil press, often with temperature control.

- Why: Peanuts have high oil content. Hot pressing in a screw press maximizes yield. Pre-treatment like shelling (using a shelling machine) and sometimes cooking/roasting (using a roasting machine) is common and beneficial.

- Our Solution: We offer robust screw presses suitable for peanuts and necessary pre-treatment equipment.

- Soybeans:

- Best Press: Screw oil press, often larger, more robust models.

- Why: Soybeans have lower oil content compared to peanuts and are harder. They require significant pressure. Pre-treatment like cracking, flaking, and cooking is essential for good yield in mechanical pressing.

- Our Solution: Our heavy-duty screw presses and complete pre-treatment systems are designed for soybeans.

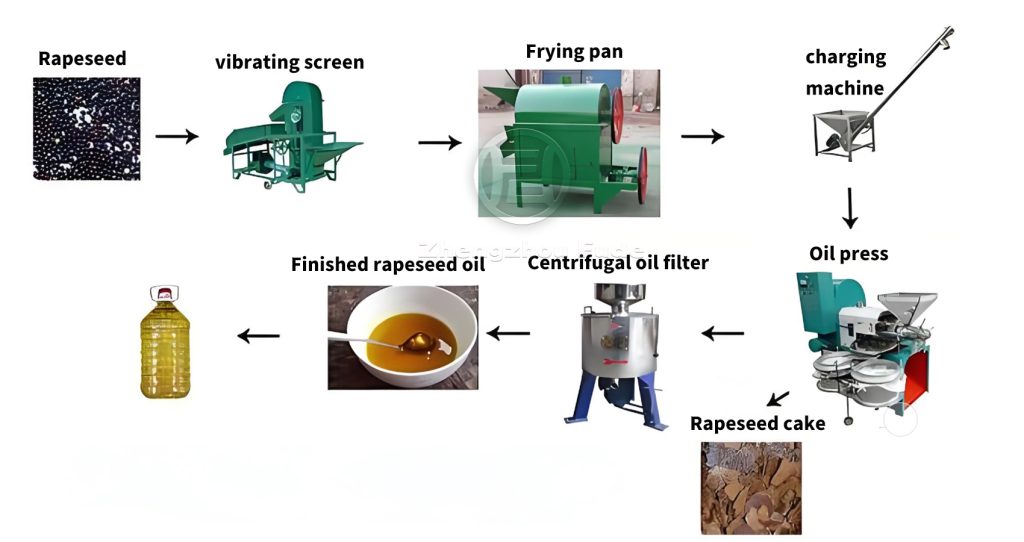

- Rapeseed (Canola):

- Best Press: Screw oil press, temperature control recommended.

- Why: Small seeds, benefit from hot pressing for yield. Pre-cooking is very common.

- Our Solution: Our versatile screw presses handle small seeds efficiently. We provide integrated cooking solutions.

- Sunflower Seeds:

- Best Press: Screw oil press.

- Why: Can be pressed with or without hulls. Dehulling first (using a shelling machine) increases capacity and reduces wear on the press. Cooking improves yield.

- Our Solution: We offer presses suitable for sunflower, along with dehulling and cooking options.

- Sesame Seeds:

- Best Press: Hydraulic oil press is often preferred, especially for high-quality aromatic oil (cold press). Screw presses can also be used (hot press).

- Why: Valued for its flavor, often cold-pressed using hydraulic method to preserve aroma. High oil content.

- Our Solution: We provide excellent hydraulic presses perfect for sesame.

- Walnuts, Almonds, Coconut, Palm Kernel:

- Best Press: Often Hydraulic oil press for cold pressing or specific quality needs. Robust screw presses can also handle harder nuts/kernels, sometimes requiring specialized designs or pre-treatment.

- Why: These can be high-value oils where quality (cold press) is key. Hardness (palm kernel) might need specific screw designs.

- Our Solution: We offer both hydraulic presses and customizable screw presses suitable for these materials, including solutions for hard kernels like palm kernel.

The key is matching the machine’s capability (pressure, temperature control, design) to the seed’s properties. As manufacturers with a comprehensive product line, we can guide you to the optimal machine for your specific raw material.

How much initial equipment investment is needed to start a small oil pressing workshop?

Starting a small workshop can range from a few thousand dollars for a basic setup (single press) to tens of thousands for a more complete small line including pre-treatment and filtering. The exact cost depends heavily on capacity and included machines.

Besides the press, you typically need equipment for cleaning seeds, cooking/roasting them (highly recommended for yield), filtering the crude oil, and potentially bottling or packaging the final product.

An oil press machine is just one part of the process. To produce good quality oil efficiently, several pieces of auxiliary equipment are often necessary or highly beneficial. We at Zhengzhou Fude Machinery offer a full range of these machines to create a complete oil mill plant.

As a provider of one-stop solutions, we can supply all the necessary auxiliary machines integrated with your chosen oil press, ensuring compatibility and smooth operation.

Related recommendations

-

Is the oil extracted by the oil press healthy

201Spiral oil press can press various oil crops, such as peanuts, soybeans, sunflower, rapeseed, walnuts, cottonseeds, etc., to meet the diverse needs of users.

View details -

How Does an Oil Press Turn Seeds into Profit?

33How Does the Press Physically Squeeze Out Oil?What Kinds of Materials Can an Oil Press Handle?Common Raw Materials:What Are the Main Products From Pressing?The Two Main Outputs:Why is the Oil Press the "Heart" of Your Mill?Core Value Creation:Esse...

View details -

What is the difference between hydraulic oil press and screw oil press

322Zhengzhou Fude Machinery integrates research and development, manufacturing, and sales, deeply understands customer needs, recommends and answers equipment questions for customers, teaches operation techniques, and produces oil presses, refiners, ...

View details -

The purpose of spiral oil press

263Spiral oil press is a common oil pressing equipment widely used in industries such as food, chemical, and pharmaceutical

View details

Oil Press Equipment and Oil Refining Machinery for Sale – Start Your Oil Press Business

Oil Press Equipment and Oil Refining Machinery for Sale – Start Your Oil Press Business

HelloPlease log in