How Does an Oil Press Turn Seeds into Profit?

Problem: Turning raw seeds into valuable oil seems complex. Agitation: Inefficiency eats profits. Solution: Understand the oil press’s core function.

An oil press physically separates oil from oil-bearing materials like seeds or nuts using immense pressure. It solves the basic need for efficient, large-scale oil extraction, forming the foundation of commercial oil production.

This simple separation process is the key to unlocking value from your raw materials. It’s the first crucial step in transforming a simple seed into valuable commodities. Let’s look closer at how this mechanical wonder works and why it’s so essential.

How Does the Press Physically Squeeze Out Oil?

Problem: How does solid seed release liquid oil? Agitation: Understanding the mechanics is key to efficiency. Solution: High pressure breaks down cell structures.

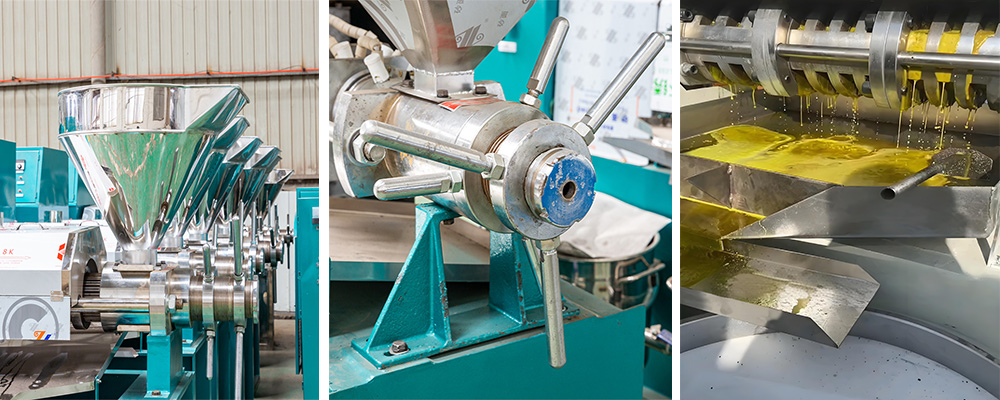

Inside a screw press, a rotating screw pushes material through a narrowing cage. This builds extreme pressure, breaking oil cells and forcing the oil out through small slots, leaving the solid cake behind.

Imagine feeding prepared oilseeds, like peanuts (cleaned, maybe crushed, and cooked/conditioned), into a special channel. This channel is the press cage. Inside it, a rotating screw pushes the material forward. The clever part is the design: the space inside the press cage gradually gets smaller towards the end, like a funnel. As the screw forces the material through this shrinking space, the pressure builds up dramatically. It can reach tens, even hundreds, of megapascals – immense force. This high pressure physically ruptures the plant cells within the seeds. The oil trapped inside is then literally squeezed out. The walls of the press cage have very fine slots or holes (press bar gaps). The extracted oil flows out through these gaps and is collected below. The remaining solid material, now with most oil removed (oil cake), is pushed out at the end of the cage. The entire process uses only mechanical force, no chemical additives. That’s why we call it physical pressing.

What Kinds of Materials Can an Oil Press Handle?

Problem: Can your specific seed be pressed? Agitation: Limiting your raw materials limits your business. Solution: Oil presses are surprisingly versatile machines.

Oil presses handle a very wide range of oil-bearing materials. This includes common oilseeds (soy, peanut, sunflower), nuts (walnut, almond – shelled), and even fruit pulp (palm, olive) or byproducts (rice bran).

The versatility of modern oil presses is a major advantage. Theoretically, almost any plant material containing sufficient oil can be processed. The most common categories include:

Common Raw Materials:

- Oilseeds: This is the largest category. Examples include soybean, peanut (groundnut), rapeseed (canola), sunflower seed, sesame seed, cottonseed (requires pre-treatment like delinting/dehulling), flaxseed, perilla seed, castor bean, tung seed, tea seed, and more.

- Nut Kernels: Many nuts are rich in oil. Common examples are walnut kernels, almond kernels, hazelnut kernels, pine nut kernels, and macadamia nut kernels. These typically need their hard outer shells removed first.

- Fruit Pulp: Some fruits store oil in their fleshy parts. Palm fruit is a major example, requiring specialized palm fruit presses. Olives are another, where pressing is one method used to produce olive oil.

- Other Materials: Certain byproducts or parts of grains are also viable. Rice bran (from rice milling) and corn germ are common examples that can be pressed for oil.

The suitability and efficiency depend on the oil content, moisture, and physical characteristics of the material, often requiring specific pre-treatment or press adjustments.

What Are the Main Products From Pressing?

Problem: Is it just about the oil? Agitation: Ignoring byproducts means lost revenue potential. Solution: Pressing yields two valuable streams: oil and cake.

Pressing produces two key products: 1) Crude Oil, the main liquid product needing filtration or refining, and 2) Oil Cake/Meal, the solid residue rich in protein, valuable as animal feed.

When you operate an oil press, you’re actually producing two distinct and valuable products simultaneously. Understanding both is key to maximizing profitability.

The Two Main Outputs:

- Crude Oil: This liquid oil is the primary target. As it comes directly from the press, it usually contains fine solid particles (meal fines or “foots”) and might have a darker color or stronger flavor. This “crude” oil needs further processing. Simple filtration (physical removal of solids) might be sufficient for some applications or local markets. More commonly, especially for food-grade oils, it undergoes refining. This involves a series of steps like degumming (removing phospholipids), deacidification (neutralizing free fatty acids), decolorizing (bleaching), and deodorizing (removing volatile compounds) to produce clear, stable, and neutral-tasting finished oil suitable for various edible or industrial uses.

- Oil Cake / Meal: This is the solid material left after the oil has been pressed out. Don’t underestimate its value! Oil cake is typically rich in protein, fiber, and minerals. It’s a highly sought-after ingredient for animal feed. The specific nutritional profile and market value depend on the original raw material (e.g., soybean meal is a major global feed commodity, peanut meal and rapeseed meal are also valuable). In many oil mill operations, the revenue generated from selling the oil cake can be a very significant portion of the total profit.

Essentially, an oil press functions as a machine that produces both oil and a valuable feed co-product.

Why is the Oil Press the “Heart” of Your Mill?

Problem: How important is the press really? Agitation: Underestimating its role weakens your operation. Solution: It’s the essential core enabling production.

The oil press is the core machine performing the essential value conversion from raw material to oil and meal. Without it, no production happens. Its efficiency directly drives the mill’s profitability and viability.

Calling the oil press the “heart” of the oil mill isn’t just a saying; it reflects its fundamental importance to the entire operation. Here’s why:

Core Value Creation:

The primary function of an oil mill is to transform raw, oil-bearing materials into valuable oil and secondary products like meal. The oil press is the specific piece of equipment where this core transformation happens. It physically performs the separation that unlocks the value contained within the raw material. Without a functioning press (or an alternative extraction method like solvent extraction), the mill simply cannot perform its basic production task.

Essential Regardless of Scale:

- For a small, local oil workshop, a single oil press might constitute the entirety of the core processing equipment. The business lives or dies by the performance of that one machine.

- For a large, complex oil processing plant with extensive pre-treatment, refining, and packaging lines, the pressing department (containing rows of large presses) or the extraction plant remains the foundational stage. Excellent raw material preparation is useless if the oil cannot be efficiently removed.

Driver of Profitability:

The press is the point where the main marketable products – oil and cake/meal – are generated. Therefore, the press’s performance characteristics directly impact the bottom line:

- Efficiency & Oil Yield: How effectively does it extract oil? Higher yield means more product from the same input.

- Reliability & Stability: Can it run continuously without frequent breakdowns? Downtime equals lost production.

These factors directly determine the mill’s overall profitability and its ability to compete in the market.

Physical Pressing or Chemical Extraction: What’s the Difference?

Problem: Pressing vs. solvent extraction – which is better? Agitation: Choosing the wrong method misaligns with your goals. Solution: Understand their distinct pros and cons.

Pressing uses mechanical force for natural oil, preserving flavor (good for quality/SMEs). Extraction uses solvents for maximum yield (good for scale/commodity oil), but is more complex and raises residue concerns.

There are two primary industrial methods for obtaining oil from plant materials: physical pressing (using machines like ours) and chemical extraction (using solvents). They operate differently and suit different needs.

| Feature | Physical Pressing (e.g., Screw Press) | Chemical Extraction (Solvent) |

|---|---|---|

| Principle | Mechanical force squeezes oil out | Chemical solvent dissolves oil, then solvent removed |

| Oil Yield | High, but leaves slightly more oil in cake (5-8% residual) | Very high, leaves minimal oil in meal (<1% residual) |

| Oil Quality | Considered more “natural”. Cold pressing preserves flavor/nutrients (e.g., Vit E). Often commands premium price. | Requires thorough refining. Potential (though regulated) solvent residue concerns among some consumers. |

| Process | Relatively simple, direct | More complex, requires solvent recovery systems |

| Investment | Flexible, suitable for small to large scale | Very high initial investment |

| Safety/Env. | No chemical hazards | Requires strict safety (fire/explosion) & environmental (solvent loss) controls |

| Best Suited For | Quality-focused oils, specialty oils, “natural” branding, small-to-medium scale, high-value nuts/seeds | Maximum yield, large-scale commodity oil production (e.g., soybean, canola), cost control focus |

In simple terms: If your focus is on preserving natural qualities, specific flavors, achieving a “chemical-free” label, or operating at a small to medium scale, physical pressing is often the preferred choice. If your goal is maximum oil recovery from large volumes of commodity seeds where cost per ton is paramount, chemical extraction offers the highest efficiency. Neither method is inherently “better”; they are different tools chosen based on raw material, scale, market positioning, and economic priorities.

Conclusion

An oil press is the vital engine separating oil from seed by physical force. It produces valuable crude oil and nutritious meal, driving the core function and profitability of any oil mill.

Related recommendations

-

Introduction to multifunctional oil press

288Spiral oil press is a multifunctional equipment with the following characteristics: simple structure, small volume, easy maintenance, diverse oil pressing materials, high oil yield, large production capacity, and continuous processing.

View details -

The difference between cold pressing and hot pressing of spiral oil press

298Spiral oil press is suitable for pressing various types of oil

View details -

Difference between hydraulic oil press and screw oil press

32Static Pressure: The Hydraulic WayDynamic Force: The Screw Press MethodWhich Press Suits Which Oilseeds Best?Hydraulic Press: Simple Use, Specialized CareScrew Press: Automated Flow, Routine MaintenanceWhich Press Type Matches Different Production...

View details -

Is olive oil produced by an oil press

221The process of extracting olive oil involves multiple steps such as picking, cleaning, crushing, pressing, separating, and filtering the olive fruit. It is recommended to use a Fude oil press to obtain high-quality olive oil products.

View details

Oil Press Equipment and Oil Refining Machinery for Sale – Start Your Oil Press Business

Oil Press Equipment and Oil Refining Machinery for Sale – Start Your Oil Press Business

HelloPlease log in