Guide to oil presses: categories and uses

- Basic Definition:Screw oil press utilizes the principle of extrusion, through the extrusion of the rotating screw shaft and the inner wall of the press chamber, the oil crops are crushed under high temperature and high pressure, so as to press out the oil and grease. This kind of oil press is simple in structure, convenient in operation, strong in continuous production capacity, and suitable for the extraction of many kinds of oils and fats.

- More Than Just “Squeezing”: The oil extraction process is far more than simple squeezing. How the pressure is applied, temperature control, and pre-treatment of the material greatly affect the oil yield and quality.

- Role in the Oil Production Line: It’s the core equipment.

| Model | 80 | 100 | 125 |

| Screw diameter | 80mm | 100mm | 125mm |

| Screw speed | 63r/min | 43r/min | 36r/min |

| Power | 5.5KW | 7.5KW | 11KW |

| production capacity | 80-150kg/H | 150-250kg/H | 250-350kg/H |

Classification and characteristics of oil presses

- Screw oil press:

- Hallmark: It can run continuously, the equipment has large output, simple maintenance in the later stage, and is applicable to a wide range of materials, such as soybeans, peanuts, oil sunflower, perilla, walnuts and so on.

- Industry Secret: The design of the screw and cage of the screw press is very critical. Different screw structures are suitable for different oilseeds. Please choose the right model according to your material.

- Hydraulic Press:

- Pros: High oil yield (especially when cold pressing), good oil quality (retaining more nutrients and flavor), low-temperature operation (suitable for cold pressing), and gentler treatment of oilseeds.

- Other Types:

- Pre-press: Usually a screw press, used in the pre-pressing-solvent extraction process of large oil plants. First, most of the oil is extracted by pre-pressing, and then the remaining oil is extracted with a solvent.

- Small Manual/Electric Oil Press: Simple structure, low oil yield, suitable for small amounts of homemade oil.

What is the difference between cold pressing and hot pressing?

- Cold Pressing:

- Definition: Oil extraction at low temperatures (usually below 40-50°C, but there is no uniform standard) to maximize the preservation of the oil’s natural flavor, color, nutrients (vitamins, antioxidants, etc.) and medicinal value.

- Hot Pressing:

- Definition: Oil extraction at higher temperatures (usually above 60°C, or even exceeding 100°C). Heating the oilseed can reduce the viscosity of the oil and increase the oil yield.

- Which is better? It depends on your needs. If you pursue high-quality oil, cold pressing is better. If you pursue high oil yield, hot pressing may be more suitable.

How does a screw oil press work?

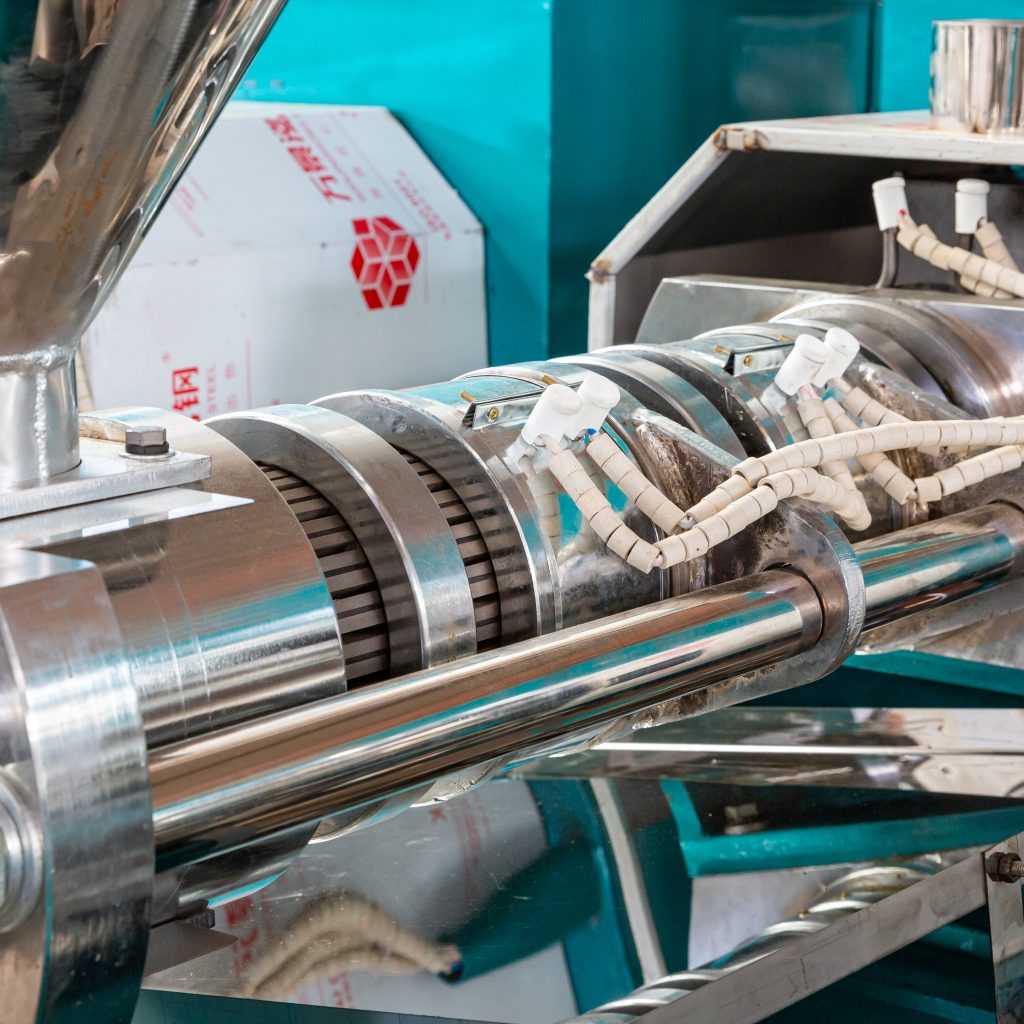

- Core Components: Screw (rotating part, pushing and pressing the material), cage (fixed part, with holes or slits for oil to flow out), feed hopper, oil outlet, cake outlet, cake adjustment mechanism.

- Working Process: The material enters from the feed hopper, and the rotating screw pushes the material forward and gradually compresses it in the pressing cage. The pitch and depth of the screw usually gradually decrease, creating increasing pressure. The oil flows out through the holes or slits in the pressing cage, and the solid residue (oil cake) is discharged from the cake outlet.

- More Than Just Pressure: The screw design also utilizes friction and shear forces to help break down the oilseed cells.

- Continuous Operation: Constant feeding of materials, constant flow of oil and cake.

How does a hydraulic oil press work?

- Core Components: Hydraulic cylinder, piston, pressing plate, filter cloth (or filter frame), oil pan.

- Working Process: The oilseed (usually crushed or made into a cake) is placed in a filter cloth or filter frame, and the hydraulic cylinder drives the piston and pressing plate to apply tremendous pressure to the oilseed. The oil flows out through the filter cloth and is collected in the oil pan.

- Intermittent Operation: Hydraulic presses need to be operated in batches: loading, pressing, and cake unloading.

How to choose the right oil press for you?

- Consider Factors:

- The type of oilseed you want to extract: Different oilseeds (such as peanuts, soybeans, sesame, rapeseed, etc.) require different oil press configurations.

- Your expected output: Home use, small oil workshop, or large oil mill?

- Your requirements for oil quality: Cold pressing or hot pressing?

- Your budget: The prices of oil presses vary greatly.

- Your site and power conditions: Oil presses require a certain amount of space and power supply.

- Your operation and maintenance capabilities: Some oil presses require more professional operation and maintenance.

- Fude Machinery is equipped with professional equipment technicians to introduce your doubts about oil press equipment and recommend you suitable solutions.

What should be paid attention to in the operation and maintenance of the oil press?

- Operation:

- Read the instructions carefully: Different oil presses have different operating procedures.

- Oilseed pre-treatment: Depending on the type of oilseed, pre-treatment such as cleaning, de-hulling, crushing, and roasting may be required.

- Control the feeding speed: Not too fast or too slow.

- Adjust the oil press: Adjust the screw gap, temperature, etc. according to the type of oilseed and the oil output.

- Observe the oil output: Clean the oil outlet and cake outlet in time.

- Safety first: When the oil press is running, do not put your hands into the feed inlet or cake outlet.

- Maintenance:

- Regular cleaning: Clean the oil and residue in the oil press.

- Regular lubrication: Lubricate the moving parts.

- Check the wearing parts: The screw, pressing cage, bearings, etc. are wearing parts and need to be checked and replaced regularly.

- Keep dry: Avoid moisture in the oil press.

Besides edible oil, what else can an oil press be used for?

- Industrial Oil: Certain oilseeds (such as castor seeds and tung oil seeds) can be used to produce industrial oils, such as lubricants and paints.

- Biodiesel: Certain oilseeds (such as rapeseed and soybeans) can be used to produce biodiesel.

- Animal Feed: The oil cake after oil extraction can be used as animal feed.

- Other Uses: Certain special oilseeds (such as nut shells) can also be processed with an oil press.

Related recommendations

-

What is the difference between hydraulic oil press and screw oil press

156Hydraulic oil press and spiral oil press are two common oil crop oil pressing equipment, which have significant differences in pressing principles, applicable oil materials, oil yield and efficiency, equipment advantages and disadvantages, etc.

View details -

Is olive oil produced by an oil press

215The process of extracting olive oil involves multiple steps such as picking, cleaning, crushing, pressing, separating, and filtering the olive fruit. It is recommended to use a Fude oil press to obtain high-quality olive oil products.

View details -

What are the advantages and disadvantages of hydraulic oil press

221What are the advantages and disadvantages of hydraulic oil press As a commonly used oil extraction equipment, hydraulic oil press has its unique advantages and disadvantages. Let me introduce it to you ,

View details -

Can the oil extracted from the oil press be consumed directly

236It is generally not recommended to drink the oil extracted from the oil press directly. If the quality of raw materials is reliable, the oil extraction process is hygienic, and it has been properly processed and stored, the extracted oil can be us...

View details

Oil Press Equipment and Oil Refining Machinery for Sale – Start Your Oil Press Business

Oil Press Equipment and Oil Refining Machinery for Sale – Start Your Oil Press Business

HelloPlease log in