small grain dryer

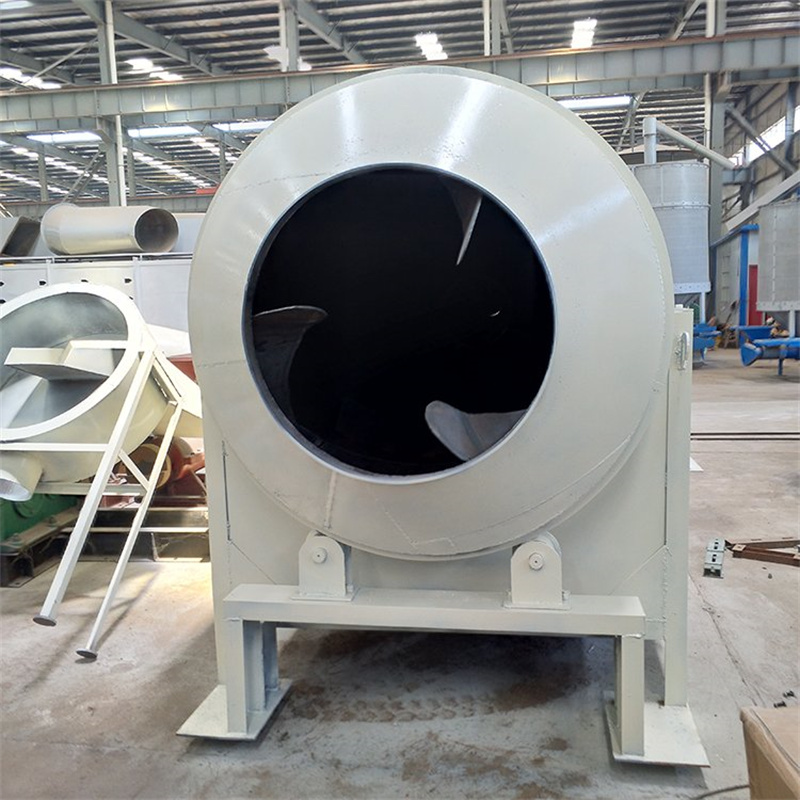

What is a corn grain dryer

driall grain dryer is one of the traditional drying equipment, with reliable operation, high flexibility, strong adaptability, and large processing capacity. It is widely used in metallurgy, building materials, chemical industry, coal washing, fertilizer, ore, sand, clay, kaolin, and so on.

Table of Contents

- What is a corn grain dryer

- The characteristics of electric grain dryer

- The working principle of farm grain dryers

- Scope of application of grain elevator dryer

- The effectiveness of using a grain silo dryer

- The advantages of law grain dryer

- Which countries have chosen our mobile grain dryer

- Diversified display of shivvers grain dryer

The characteristics of electric grain dryer

excel grain dryer has a large processing capacity, low fuel consumption, and low drying cost. The dryer has the characteristic of high temperature resistance and can use high-temperature hot air to quickly dry materials. Strong scalability, design takes into account production surplus, and even if the output increases slightly, there is no need to replace equipment. The equipment adopts a self-aligning tugboat structure, with good coordination between the tugboat and the rolling ring, greatly reducing wear and power consumption. The specially designed blocking wheel structure greatly reduces the horizontal thrust caused by equipment tilting operation. Strong overload resistance, smooth operation of the cylinder, and high reliability.

The working principle of farm grain dryers

The grain dryer machine mainly consists of rotating body, lifting plate, transmission device, support device, and sealing ring components. A dryer is a cylinder that is slightly inclined towards the horizontal direction. Materials are added from the higher end, and high-temperature flue gas flows into the cylinder in parallel with the material. As the cylinder rotates, the material moves to the lower end due to gravity. A copying plate is installed on the inner wall of the cylinder to pick up and sprinkle the material, increasing the contact surface between the material and the airflow, in order to improve the drying rate and promote the material to move forward. The dried product is collected from the bottom.

Scope of application of grain elevator dryer

- Chemical, mining, metallurgy and other industries, such as ore, slag, coal, metal powder, clay, diatomaceous earth, kaolin.

- Agriculture, feed, and fertilizer industries, such as straw, grass, leaves, fish meal, corn sauce, starch residue, distiller’s grains, medicinal residue, fruit residue, soy sauce residue, sugarcane residue, peat, organic compound fertilizer, sludge, aquatic product waste, food factory waste, slaughterhouse waste, organic fertilizer, inorganic fertilizer, and ammonium phosphate fertilizer.

- Dry powdered and granular materials with special requirements. Such as various crystals, lightweight calcium carbonate, activated clay, magnetic powder, graphite, inorganic mud, clay, lime slurry, ore mud, phosphorus slag, aluminum plant red mud.

- Materials that require low-temperature drying and require continuous drying in large quantities.

The effectiveness of using a grain silo dryer

The industrial grain dryer is mainly used to dry granular materials within a certain humidity range, such as yellow sand used in the dry powder mortar industry and various specifications of molding sand used in the casting industry. Blast furnace slag used in the building materials and cement industry. Small particle clay, used in the chemical industry for small particle materials that do not undergo chemical changes, are not afraid of high temperature and smoke pollution. According to the moisture requirements of different industries for dried materials, the moisture content of the dried materials can reach below 1-0.5%.

The advantages of law grain dryer

- The mini grain dryer has a large processing capacity, low fuel consumption, and low drying cost.

- It has the characteristic of high temperature resistance and can use high-temperature hot air to quickly dry materials. Strong scalability, design takes into account production surplus, and even if the output increases slightly, there is no need to replace equipment.

- The self insulation thermal efficiency of the cylinder can reach over 80% (traditional single cylinder dryers have a thermal efficiency of only 35%), improving the thermal efficiency by 45%.

- The fuel can adapt to coal, oil, and steam. Can bake block materials, granular materials, and powdered materials below 20mm.

- Compared to a single drum dryer, it reduces the floor area by about 50%, reduces civil engineering investment by about 50%, and reduces electricity consumption by less than 60%.

Which countries have chosen our mobile grain dryer

Our drum dryers are sold to Southeast Asia, Europe, America, and other regions, and have received widespread praise.

Diversified display of shivvers grain dryer

- The small grain dryer machine is one of the traditional drying equipment, with reliable operation, high flexibility, strong adaptability, and large processing capacity. It is widely used in metallurgy, building materials, chemical industry, coal washing, fertilizer, ore, sand, clay, kaolin, sugar and other fields.

- A three cylinder dryer is a type of dryer that shortens the external dimensions of the dryer body by replacing the single cylinder body with three stacked cylinders. When the machine is in operation, materials and hot air flow enter the inner to outer cylinder in sequence. After the Z-shaped reciprocating flow of the machine body, the heat energy is fully utilized to dry the materials before unloading.

- The full name of a industrial box dryer is a box type fruit and vegetable dryer. This equipment dries evenly, with fast speed and high efficiency, and the materials are not easy to stick. It can achieve automatic temperature control and moisture removal, which can keep the dried materials in a better shape, maintain the color and shape of the dried materials, and improve product quality.

Oil Press Equipment and Oil Refining Machinery for Sale – Start Your Oil Press Business

Oil Press Equipment and Oil Refining Machinery for Sale – Start Your Oil Press Business