Commercial hot press oil press

What is a hot press oil press

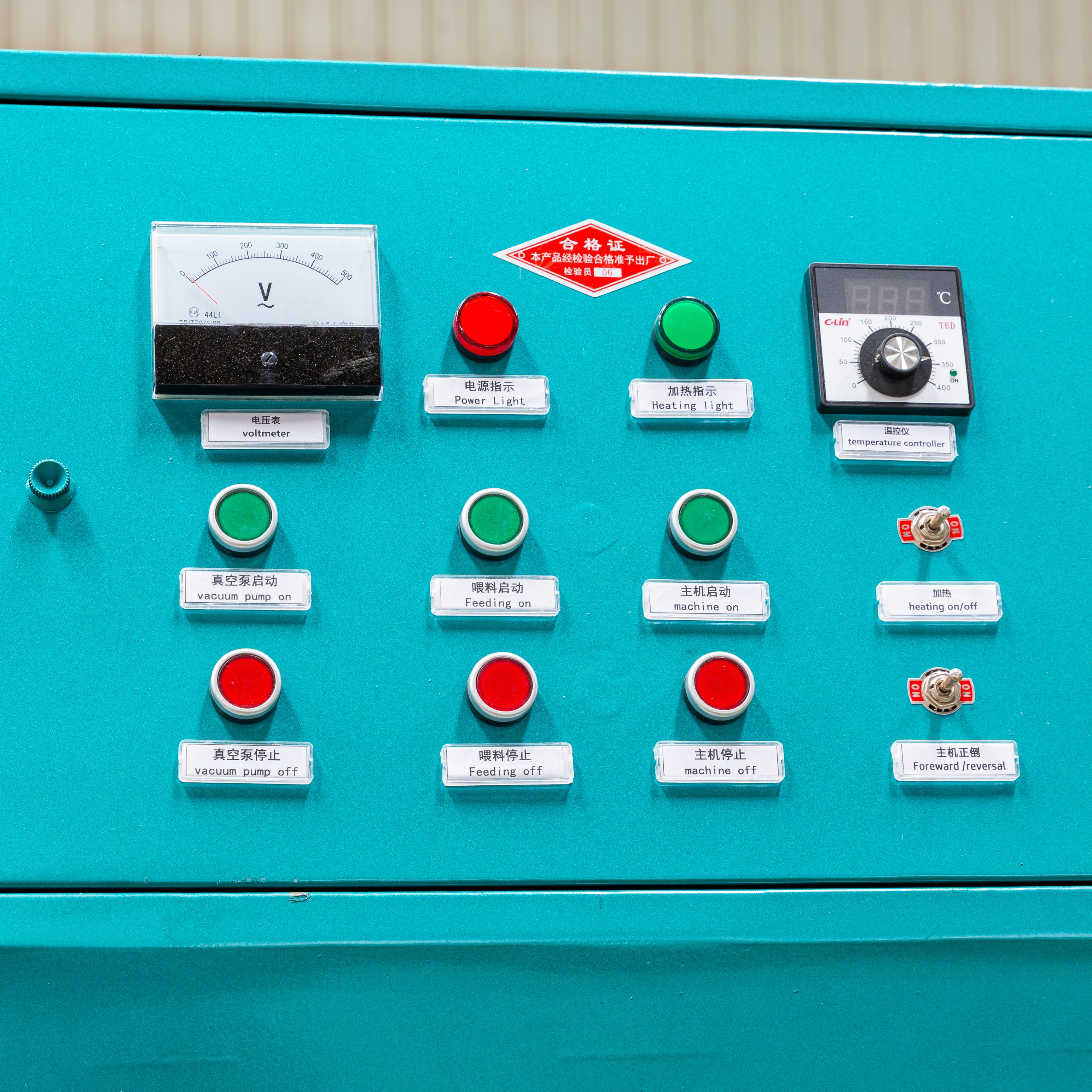

Hot press oil press, also known as fully automatic oil press. Apart from feeding, there is basically no need for other operations, brake temperature control, vacuum filtration operation is simple, occupies less space, and has a high oil output rate. It is a technology introduced from South Korea more than a decade ago. By temperature control, the actual oil output rate can be increased by 10-30%.

Table of Contents

- What is a hot press oil press

- The characteristics of hot press oil press

- The working principle of hot press oil press

- Scope of application of hot press oil press

- The effectiveness of using a hot press oil press

- The advantages of hot press oil press

- Which countries have chosen our hot press oil press

The characteristics of hot press oil press

Hot pressing is just the opposite of cold pressing. Oil plants are pressed after heating. This way of pressing can be pressed clean at one time. The produced Youbing (Deep-fried round and flat dough-cake) has almost no oil content, so Youbing (Deep-fried round and flat dough-cake) is a completely deoiled cake, which can be used in making oil-free material cakes.

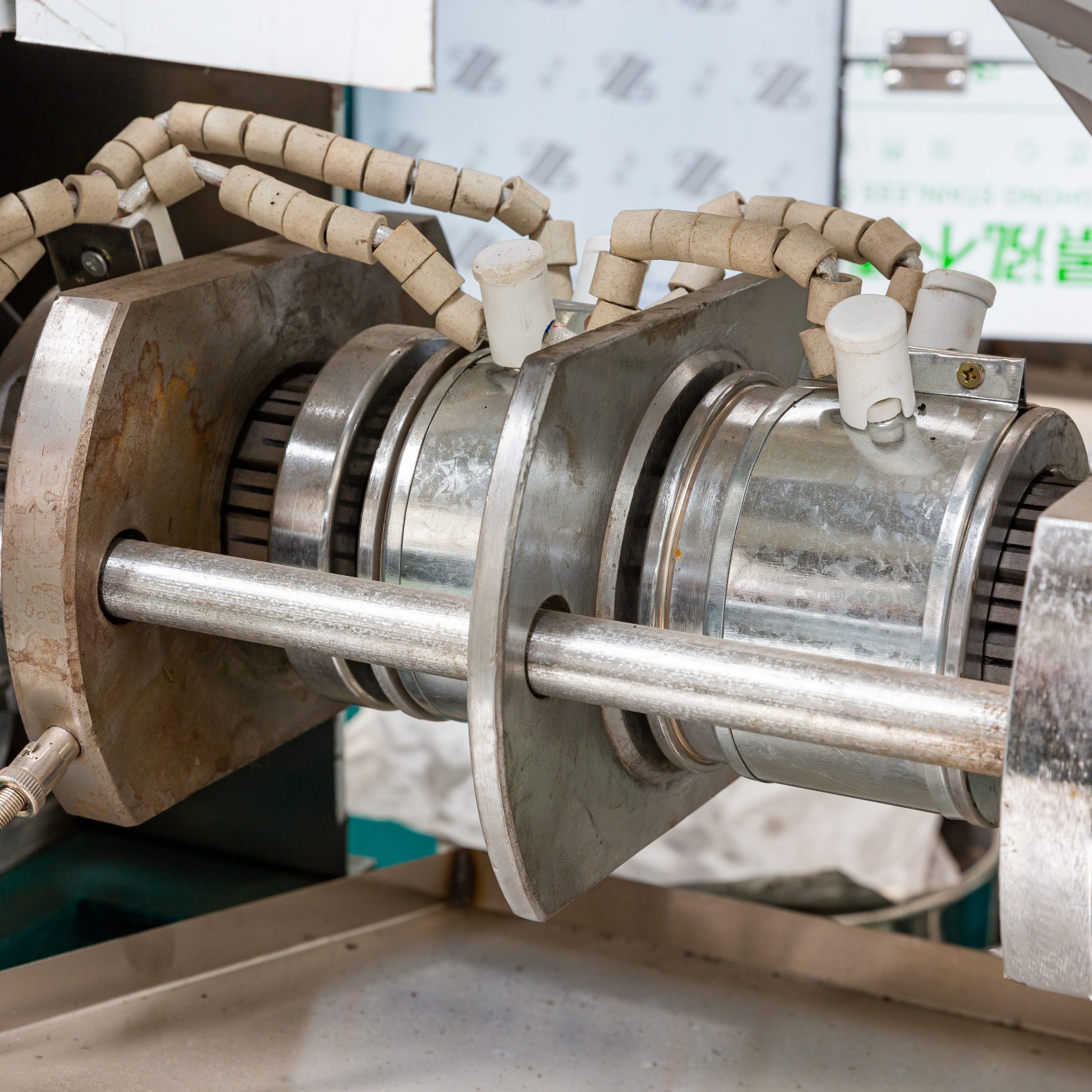

The working principle of hot press oil press

When the oil press is running, the processed material is carried as a hopper, and the oil enters the pressing chamber from the hopper. The spiral of the squeezed snail is pushed inward for pressing. Due to the fact that the material embryo is in operation in the oil press chamber, under high pressure conditions in the chamber, there is a significant frictional resistance between the material embryo, the screw, and the chamber. This can cause friction between the material and the material, resulting in relative motion.

Scope of application of hot press oil press

The hot press oil press is a versatile machine that can be used to press various raw materials such as vegetable seeds, sunflower seeds, peanuts, flaxseeds, soybeans, camellia seeds, etc. It can assist in the action of mechanical external forces, by increasing temperature, activating oil molecules, and squeezing oil out of the oil material.

The effectiveness of using a hot press oil press

The power of hot pressing oil is reduced and transmitted to the main shaft. The screw installed on the main shaft rotates, continuously pushing the oil between the threads forward. As the space between the pressing chamber and the screw gradually shrinks, the density of the oil increases, and the pressure gradually increases. During the pressing process, friction occurs between the oil particles and between the oil and the parts, generating heat. This constitutes the two major elements of the oil pressing process: pressure and heat. The tissue cells of the oil are broken, and the oil overflows from the oil line, obtaining pure oil.

The advantages of hot press oil press

The advantage of hot pressing is that the pressed oil is very fragrant and mellow. The oil added after hot pressing has a more oily taste than cold pressing. However, due to hot pressing, there may be a phenomenon of clogging the pot at times. When pressing, it is important to note that the material should not be added too quickly, and the appropriate amount of material should be cut according to the amount of oil produced during pressing.

Which countries have chosen our hot press oil press

Our hot press oil presses are sold to more than 40 countries worldwide, including Germany, the United Kingdom, France, Italy, Spain, etc. Our products are highly welcomed and loved.

Oil Press Equipment and Oil Refining Machinery for Sale – Start Your Oil Press Business

Oil Press Equipment and Oil Refining Machinery for Sale – Start Your Oil Press Business