cool press coconut oil

The cold oil press has pure natural characteristics, avoiding the adverse effects of traditional high-temperature oil pressing processing. Cold pressed finished oil retains the natural flavor and color of the oil, and fully preserves the physiological active substances in the oil. Cold pressed oil has the characteristic of original flavor.

Table of Contents

- The characteristics of cold press oil press

- The working principle of pecan oil press

- Scope of application of lavender oil press

- The effectiveness of using a almond oil press

- The advantages of flaxseed oil press

- Which countries have chosen our cooking oil pressing machine

The characteristics of cold press oil press

Under the condition that the oil plants are not heated, they are directly put into the oil press for pressing after screening. This kind of pressing method is difficult to press clean at one time, and the Youbing (Deep-fried round and flat dough-cake) produced also has oil content. Some Youbing (Deep-fried round and flat dough-cake) that need this type of pressing at one time have less oil content, but they are not completely oil free.

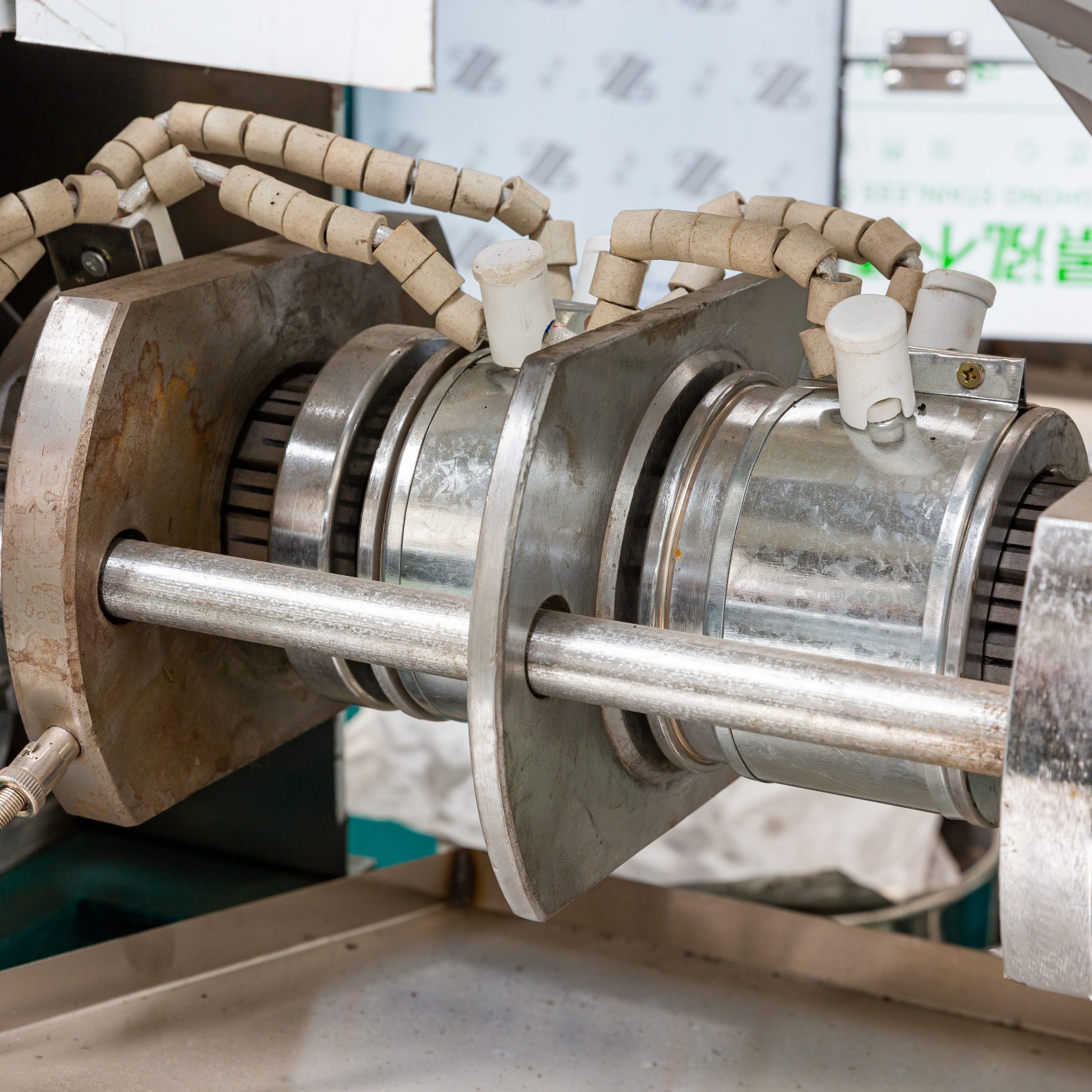

The working principle of pecan oil press

Using the continuous rotation of the screw shaft to drive the screw to reduce the lead or gradually increase the root diameter, the volume of the pressing chamber space is continuously reduced, resulting in a pressing effect; The extracted oil is squeezed out from the gaps in the squeezing cage, while the residue is pressed into crumbs and continuously discharged from the end of the squeezing shaft.

Scope of application of lavender oil press

The grape seed oil press can press soybean, high mustard pickled Chinese cabbage seed, cottonseed, peanut, sesame and other materials. However, these raw materials must be carefully selected, otherwise the quality of cold pressed oil will be seriously affected due to the different maturity of the materials and the harmful substances contained in the materials (such as aflatoxin in moldy oil and gossypol toxin in cottonseed).

The effectiveness of using a almond oil press

The power of hazelnut oil press oil is reduced and transmitted to the main shaft. The screw installed on the main shaft rotates, continuously pushing the oil between the threads forward. As the space between the pressing chamber and the screw gradually shrinks, the density of the oil increases, and the pressure gradually increases. During the pressing process, friction occurs between the oil particles and between the oil and the parts, generating heat. This constitutes the two major elements of the oil pressing process: pressure and heat. The tissue cells of the oil are broken, and the oil overflows from the oil line, obtaining pure oil.

The advantages of flaxseed oil press

The advantage of cotton seed oil press is that the color is relatively light. When pressing oil, there will be no foam and no sludge pan. The color is beautiful.

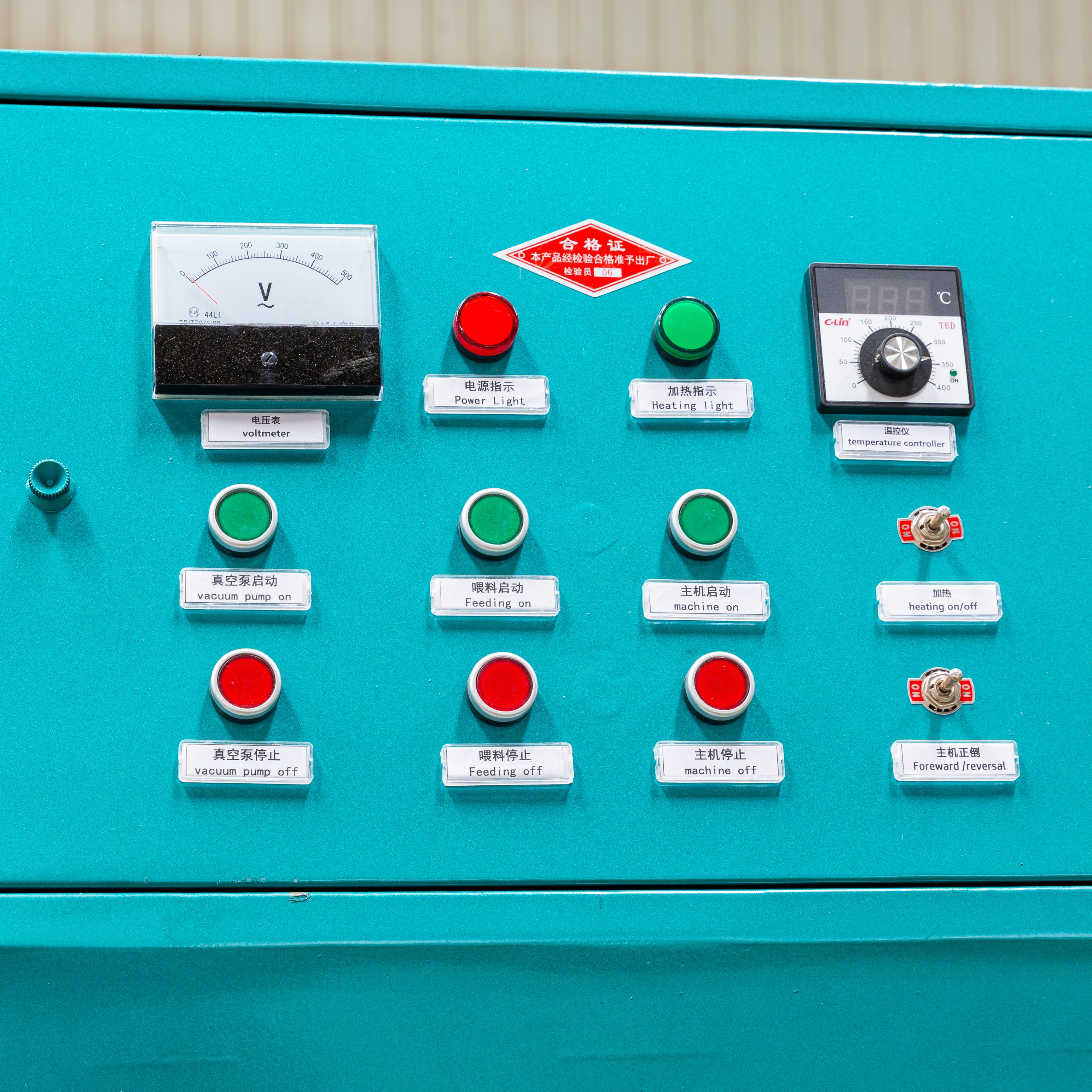

- Adopting vacuum filtration, rapid purification, and automatic temperature control technology, the oil output rate is high, about 3% higher than that of ordinary hydraulic oil presses, making installation convenient.

- The oil has high purity and can be consumed directly after vacuum filtration

- Oil extraction only requires a 10-20 square meter factory building.

- The surface of the fuel dispenser is chrome plated stainless steel.

- Efficient, energy-saving, labor-saving, easy to operate, and easy to maintain.

Which countries have chosen our cooking oil pressing machine

Our cold press oil presses are sold to more than 40 countries worldwide, including Germany, the United Kingdom, France, Italy, Spain, etc. Our products are highly welcomed and loved.

Oil Press Equipment and Oil Refining Machinery for Sale – Start Your Oil Press Business

Oil Press Equipment and Oil Refining Machinery for Sale – Start Your Oil Press Business