Analysis of raw materials for oil press processing

Understanding your raw materials is the first step toward efficient oil production. Let’s explore what you can actually use.

Which crops and seeds can be used for oil extraction?

Wondering what you can actually press oil from? Uncertainty costs time and money. We list common and niche oil materials suitable for pressing.

You can extract oil from almost any plant seed, fruit, nut, or germ with high enough oil content, like soybeans, peanuts, sunflower, rapeseed, palm kernel, and even walnuts or castor beans.

Determination of raw materials for oil processing

At Zhengzhou Fude Machinery, we’ve built equipment for a wide range of materials. The primary requirement is a significant oil content that can be released through pressure.

- Common Oil Materials: These are widely cultivated and processed globally. Our equipment frequently handles:

- Soybeans

- Peanuts (Groundnuts)

- Rapeseed (including Canola)

- Sunflower Seeds

- Cottonseed

- Sesame Seeds

- Flaxseed (Linseed)

- Palm Fruit & Palm Kernel

- Coconut (Copra)

- Olives

- Corn Germ

- Rice Bran

- Special or Niche Oil Materials: These might be less common globally but important regionally or for specific uses:

- Nuts: Walnuts, Almonds, Hazelnuts

- Seeds: Tea Seeds, Castor Seeds (Industrial), Tung Oil Seeds (Industrial), Neem Seeds, Perilla Seeds, Peony Seeds, Grape Seeds

- Fruits: Sea Buckthorn

The choice depends on availability, market demand for the oil and cake, and the processing capabilities. We can help you assess the suitability of your specific material.

What are the main classifications of common oil materials?

Organizing oil materials seems complex. This makes choosing equipment hard. We classify materials simply for easy understanding based on source and oil content.

Oil materials are classified by the part containing oil (seed, fruit, nut, germ, bran) or by oil content (high >40%, medium 20-40%, low <20%). Examples include seeds like soybeans, fruits like olives.

Understanding these classifications helps in selecting the right processing approach and equipment. Let’s break it down further.

Classifying by Source Part

Different parts of a plant store oil. This affects how they need to be handled and pressed.

| Classification | Examples | Fude Machinery Focus |

|---|---|---|

| Seed Type | Soybeans, Peanuts, Rapeseed, Sunflower, Sesame | Main category; wide range of screw presses offered |

| Fruit Type | Olives, Palm Fruit, Sea Buckthorn | Specialized presses/lines available (e.g., palm) |

| Nut Type | Walnuts, Almonds, Palm Kernel, Coconut Meat | Robust presses needed; consider pre-crushing |

| Germ Type | Corn Germ, Wheat Germ | Often requires specific pre-treatment |

| Bran Type | Rice Bran | Low oil; often involves solvent extraction |

Classifying by Oil Content

The amount of oil influences the pressing strategy and equipment choice.

| Oil Content Category | Approximate Range | Examples | Pressing Considerations |

|---|---|---|---|

| High Oil Content | >40% | Peanuts, Sesame, Sunflower, Rapeseed, Palm Kernel | High yield potential; manage oil drainage |

| Medium Oil Content | 20%-40% | Soybeans, Cottonseed, Flaxseed, Tea Seeds | Good yield; pre-treatment often crucial |

| Low Oil Content | <20% | Corn Germ, Rice Bran | Requires efficient pressing/leaching; cake value important |

As manufacturers, we consider these classifications when designing presses. High-oil materials need efficient oil drainage, while low-oil materials require maximum pressure and optimal pre-treatment for profitability.

Characteristics and oil yield of different oilseeds

Soybean (Glycine max)

- Properties: Soybeans are unique with relatively low oil content (around 18-20%) but very high protein (around 40%). Refined soybean oil is neutral tasting and rich in linoleic acid.

- Oil Yield (Pressing): Using only mechanical pressing, the oil yield is modest, typically 14-18%. This is why large plants often use pre-pressing followed by solvent extraction to maximize recovery, nearing the theoretical content. Our screw presses are designed for efficient soybean pre-pressing.

- Main Uses: Primary use is for edible oil (requires refining). The high-protein soybean meal is a crucial animal feed ingredient and often the main value driver. Soy is also used in foods like tofu and soy milk.

Peanut (Arachis hypogaea / Groundnut)

- Properties: Peanuts boast high oil content (45-50%) and significant protein (around 25%). Peanut oil is known for its distinct, pleasant aroma and is rich in oleic acid.

- Oil Yield (Pressing): Mechanical pressing yields are excellent, often reaching 40-48%. Hot pressing, which Fude Machinery’s cookers facilitate, increases yield further and enhances the characteristic roasted aroma popular in many markets.

- Main Uses: Widely consumed as edible oil. Also used for peanut butter, snacks. The remaining cake is a valuable feed component.

Rapeseed (Brassica napus / Canola)

- Properties: These seeds have high oil content (40-45%). Modern varieties, known as Canola, are bred for low levels of erucic acid and glucosinolates, making the oil healthy and the meal safe for feed.

- Oil Yield (Pressing): Pressing yields are good, typically 35-42%. Hot pressing after proper cooking is the standard method to achieve these yields. Our integrated lines handle rapeseed efficiently.

- Main Uses: A major global source of edible oil (rapeseed/canola oil). Rapeseed meal is an important protein feed. The oil is also a significant feedstock for biodiesel production.

Curious about niche oils like flaxseed or walnut? Limited knowledge prevents exploring these potentially high-value markets. We highlight features of special materials.

Flaxseed is rich in Omega-3 (30-40% yield), needing careful handling. Walnuts have very high oil content (55-65%) and good flavor, often cold-pressed. Palm kernel oil (40-50% yield) is high in saturated fats.

Processing special materials often requires specific knowledge and equipment capabilities, which Zhengzhou Fude Machinery can provide.

Flaxseed (Linum usitatissimum / Linseed)

- Special Features: Its main selling point is high α-linolenic acid (ALA) content, a key Omega-3 fatty acid. However, this makes the oil prone to oxidation, demanding careful, often cool, processing and storage.

- Oil Yield (Pressing): Typically around 30-40%. To preserve the valuable ALA, cold pressing is common, which our hydraulic presses or specially configured screw presses can perform.

- Main Uses: Edible oil, primarily as a nutritional supplement due to its Omega-3 content and distinct flavor. Industrially, as linseed oil, it’s a traditional drying oil in paints and varnishes. The meal is used in feed.

Walnut (Juglans regia)

- Special Features: Walnuts contain exceptionally high oil levels (60-70%). The oil is prized for its rich flavor and high content of polyunsaturated fats (Omega-3 and Omega-6). Raw material cost is significantly higher than common oilseeds.

- Oil Yield (Pressing): High yields of 55-65% are achievable. Cold pressing or low-temperature pressing is preferred to maintain the delicate flavor and nutritional profile. Hydraulic presses are often suitable.

- Main Uses: Marketed as a high-end gourmet edible oil for finishing dishes, dressings, or baking. Walnut meal also retains high nutritional value.

Palm Kernel (Elaeis guineensis Kernel)

- Special Features: Extracted from the seed inside the palm fruit, palm kernel oil is distinct from palm oil (from the fruit flesh). It has very high oil content (45-55%) and is rich in saturated fatty acids, particularly lauric acid, making it semi-solid at room temperature.

- Oil Yield (Pressing): Around 40-50%. Processing typically involves cracking the hard shell, crushing the kernel, and hot pressing using robust screw presses designed to handle the abrasive material.

- Main Uses: Widely used in the food industry (margarine, confectionery, baked goods), cosmetics, and soap making due to its properties. Palm kernel meal is a common animal feed.

Oil Yield Ranking (Approximate Pressing Yields)

This ranking provides a general idea. Actual results depend heavily on specific variety, quality, pre-treatment, and the efficiency of the pressing equipment (like those from Fude Machinery).

- Highest (>55%): Coconut Meat (Copra), Walnuts

- Very High (40%-55%): Peanuts, Sesame, Palm Kernel, High-Oil Sunflower/Rapeseed Varieties

- Relatively High (30%-40%): Standard Rapeseed, Standard Sunflower Seeds, Flaxseed, Tea Seeds, Almonds

- Medium (15%-30%): Soybeans, Cottonseed, Corn Germ

- Relatively Low (<15%): Rice Bran

We help clients analyze these factors to choose the most profitable materials for their situation and equipment.

Investing in proper material preparation and quality control pays off significantly in higher yields, better product quality, and longer equipment life.

Is the same oil press suitable for all materials?

Thinking one press model fits all materials? This common misconception leads to inefficiency, lower yields, and potentially poor results. We explain why specific presses work best.

No, the same oil press is generally not optimal for all materials. Key design elements like the screw configuration, pressure capability, and cage structure need to be matched to the specific seed or nut.

While some presses offer versatility, maximum efficiency usually comes from a machine tailored to the primary material being processed.

Why One Size Doesn’t Fit All

As manufacturers at Zhengzhou Fude Machinery, we engineer presses based on material properties:

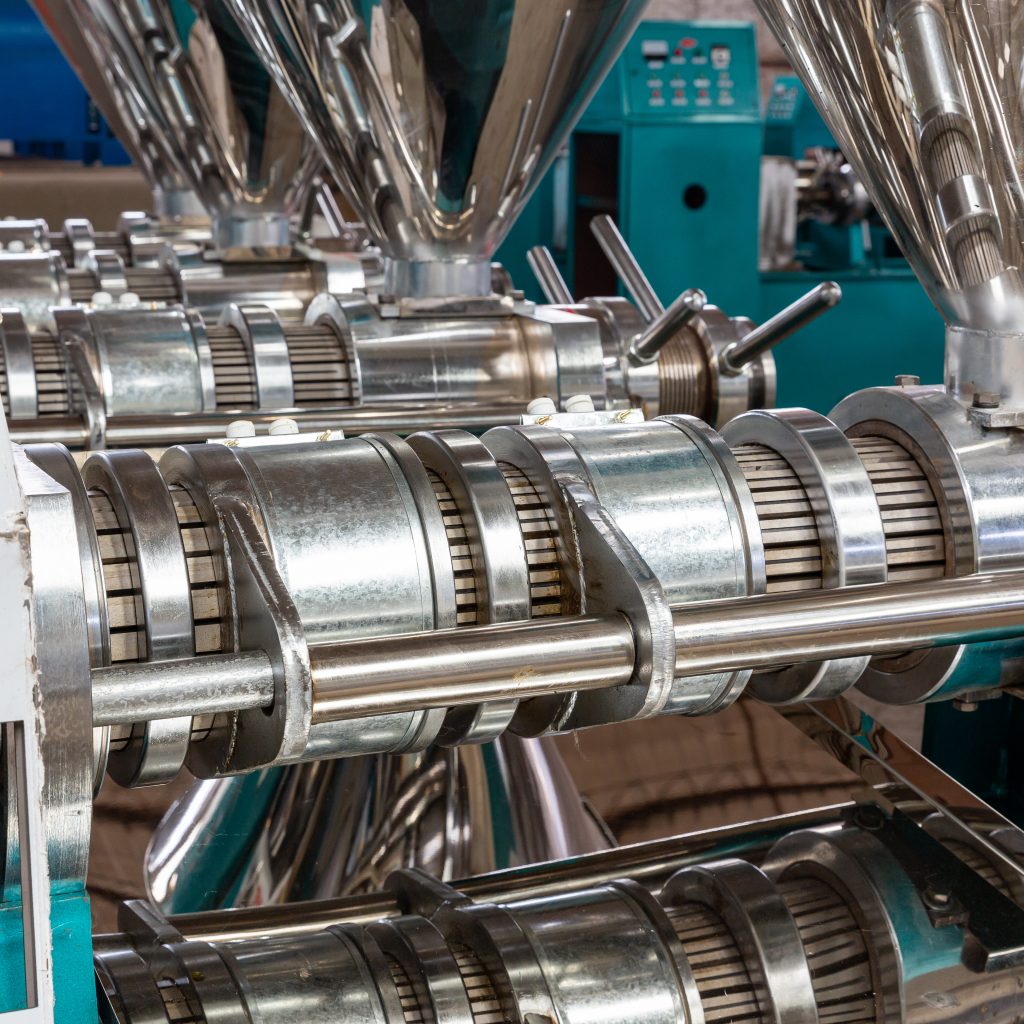

- Structural Design: The core components – the press screw (worm shaft) and the press cage (barrel) – are critical.

- Screw: The design (pitch, groove depth, compression ratio) dictates how pressure builds. A screw optimized for high-oil peanuts is very different from one designed for lower-oil soybeans. We offer customized screw designs.

- Cage: The spacing and shape of the openings (oil discharge gaps) in the cage must allow efficient oil drainage without letting solids escape. This varies by material.

- Hardness and Size: Materials like hard-shell palm kernels or walnuts require significantly higher pressure and more robust, wear-resistant press components. Specialized pre-crushing equipment might also be needed, which we also supply.

- Oil Content: High-oil materials compress and release oil differently than low-oil materials. The press needs to manage the large volume of oil from high-yield seeds effectively.

- Hydraulic Presses: These operate differently (batch vs. continuous screw press) and are often better suited for specific applications like cold pressing sesame or walnuts, where preserving quality is paramount or forming a stable cake in a screw press is difficult.

Our Recommendation

When you contact us, clearly state the main material(s) you intend to press. This allows us to recommend the most suitable Fude Machinery model or discuss necessary customizations. Using a general-purpose press for a specific, demanding material often results in subpar performance – lower yield, higher residual oil in the cake, or increased wear.

Do some special materials require special pre-treatment steps?

Skipping pre-treatment seems like a shortcut? But doing so drastically lowers yield and quality, especially for more complex or special materials. We outline essential steps.

Yes, absolutely. Beyond basic cleaning, many materials need specific pre-treatment to break down cell walls, adjust moisture, remove undesirable components, or improve handling for efficient oil extraction.

Proper pre-treatment is not optional; it’s a cornerstone of maximizing oil yield and ensuring the quality of both oil and cake.

Examples of Special Pre-treatment:

At Zhengzhou Fude Machinery, we provide the full range of necessary pre-treatment equipment:

- Soybeans: Typically require crushing (breaking the bean), softening (heating to adjust moisture and plasticity), and flaking (rolling into thin flakes) to rupture cell structures effectively before pressing or solvent extraction.

- Cottonseed: Needs ginning (fiber removal), shelling/dehulling, separation of kernels from hulls, crushing/flaking, and cooking/steaming (crucial for reducing gossypol toxicity and improving oil yield).

- Palm Fruit: Requires sterilization (steam to deactivate enzymes), threshing (removing fruit from bunches), digesting (mashing the fruit flesh), before pressing.

- Palm Kernel: After separating from the palm fruit fiber and shell, kernels need crushing and cooking/steaming before pressing.

- Rice Bran: Contains enzymes causing rapid FFA increase. Requires immediate stabilization (usually steam heating) after milling, and often puffing/expanding to improve oil release, especially for solvent extraction.

Which materials are suitable for cold pressing and hot pressing processes?

Cold press or hot press – which is right? Making the wrong choice impacts your oil’s quality, flavor, nutritional value, and the overall yield. We guide you on selecting the best process.

Cold pressing (<60°C) preserves natural qualities, suiting olive, flaxseed, walnut. Hot pressing (after cooking) maximizes yield for common seeds like soybean, peanut, rapeseed, cottonseed, especially if refining follows.

The choice between cold and hot pressing fundamentally depends on the target product characteristics and economic goals.

Cold Pressing Explained

- Definition: Oil extraction occurs without intentional heating of the material before pressing, or with only minimal temperature rise due to friction (generally kept below 60°C / 140°F).

- Suitable Materials: Ideal for oils where preserving the natural flavor, aroma, color, and heat-sensitive nutrients (like certain vitamins or antioxidants) is the priority. Examples include:

- Extra Virgin Olive Oil

- Flaxseed Oil

- Perilla Seed Oil

- Walnut Oil, Almond Oil

- Peony Seed Oil

- Some high-quality Sesame Oils

- Characteristics: Typically results in lower oil yield compared to hot pressing. The crude oil might appear cloudier (containing more phospholipids, waxes) but retains its original sensory and nutritional profile. Fude Machinery offers hydraulic presses and specialized screw presses suitable for cold pressing.

Hot Pressing Explained

- Definition: The oil material undergoes significant heating, usually through steaming or roasting in a cooker, before entering the press.

- Suitable Materials: Applied to most common oilseeds, especially when maximizing oil yield is a key objective, or when the crude oil is destined for refining anyway. Examples include:

- Soybeans

- Peanuts (especially for aromatic oil)

- Rapeseed (Canola)

- Sunflower Seeds

- Cottonseed

- Sesame (for dark, toasted aroma oil)

- Characteristics: Achieves higher oil yield because heat reduces oil viscosity, ruptures cells more effectively, and denatures proteins. The resulting oil is often darker, may have a cooked or roasted flavor, and might lose some heat-sensitive nutrients. Our standard screw presses are often paired with cookers for efficient hot pressing.

Making the Choice

Consider: What is your final product goal? Are you selling high-value “virgin” or “cold-pressed” oil focused on flavor and nutrition, or are you producing a commodity oil for refining, where yield is paramount? We can advise on the best process and equipment configuration for your specific needs.

Strategy for Value Maximization

At Zhengzhou Fude Machinery, we encourage clients to consider the entire process, including by-product value:

- Analysis of the composition: To know the main specifications of the raw material for oil extraction: protein, residual oil, fiber, moisture content.

- Ensuring Quality: Pressed oil cakes should be stored properly, kept cool and dry to prevent mold growth.

- Consider Further Processing: Sometimes grinding the cake into meal or pelletizing it can improve handling, storage, and marketability.

- Price Appropriately: Base pricing on quality (especially protein content) and prevailing market rates for comparable products (e.g., soybean meal often sets a benchmark).

Conclusion

Selecting the right oil materials and matching them with the correct pressing technology and pre-treatment is vital for success. We hope this guide helps you make informed decisions for efficient oil production.

Related recommendations

-

Advantages and disadvantages of oil press

255As a device that converts oil crops into edible oil, the oil press has its unique advantages and disadvantages. Please refer to the specific introduction

View details -

How to make oil easily with a small oil press?

25Why Use a Small Oil Press for Homemade Edible Oil? Fresh, Healthy, and Cost-Effective?Which Oil Seeds Are Best for Easy Oil Pressing?How to Use a Small Oil Press for Edible Oil?Do Seeds Need Special Treatment Before Pressing? How to Simply Boost ...

View details -

What are the advantages of an oil press

448Spiral oil press equipment is widely used in various fields such as obtaining plant seed oil and separating and extracting chemical raw materials. Such as sesame, peanut, rapeseed, olive, etc.

View details -

How to Start Your Own Vegetable Oil Pressing Business?

33What Are the Basic Steps Needed to Start an Oil Mill?Do Different Oilseeds (Soybean, Peanut, Rapeseed, etc.) Require Different Oil Presses?How Do I Choose the Right Oil Press Model Based on My Expected Production Volume?Matching Capacity to NeedsB...

View details

Oil Press Equipment and Oil Refining Machinery for Sale – Start Your Oil Press Business

Oil Press Equipment and Oil Refining Machinery for Sale – Start Your Oil Press Business

HelloPlease log in