plant oil press

Cold and hot double press pecan oil press

The oil seeds press machine is mainly used as an oil press for individual home processing. This product belongs to a type of hydraulic fully automatic oil press, with a small output but simple and convenient. The main product now is the screw oil press. There are also spiral oil presses for cold pressing, which are relatively inexpensive but have a low oil yield.

Table of Contents

- Cold and hot double press pecan oil press

- Working video ofoil pressing machine for home use

- oil press machine industrial parameters

- What are the complete sets of equipment for theoil press machine for home use production line?

- Working principle of oil press at home

- What are the advantages of lavender oil press?

- castor oil press details are thoughtful and unique

- Reference map of extractable oil crops

- Good physical pressing effect and natural nutrition

- Customer cooperation cases

- Factory loading and departure site

- What are the main factors that affect the oil extraction efficiency of an oil press?

Working video ofoil pressing machine for home use

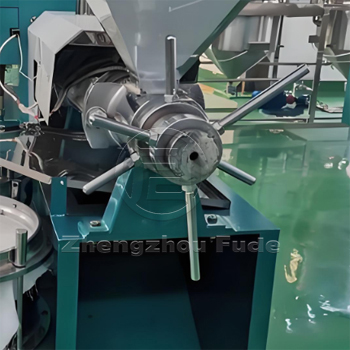

The oil extraction principle of a screw press mainly uses the oil extraction screw to rotate in the pressing chamber and squeeze out the oil material. After adding the oil at the feeding port, the screw rotates to push the oil into the pressing chamber, causing the oil to gradually deform and separate from the oil through strong pressure. Meanwhile, the squeezed oil residue is discharged from the machine through the oil residue outlet and stored in the waste residue storage tank.

oil press machine industrial parameters

| Oil press model | 60 type | 70 type | 80 type | 100 type | 125 type | 150 type |

| Squeezing chamber diameter | 55mm | 65mm | 80mm | 101mm | 125mm | 150mm |

| Squeezing screw speed | 52r/min | 48r/min | 47r/min | 38r/min | 36r/min | 35r/min |

| Squeezing screw speed | 2.2kw | 3kw | 5.5kw | 7.5kw | 15kw | 18.5kw |

| Processing capacity | 30-60kg/h | 50-80kg/h | 65-130kg/h | 140-280kg/h | 300-400kg/h | 500-600kg/h |

| Overall weight | 220kg | 280kg | 780kg | 1100kg | 1280kg | 1420kg |

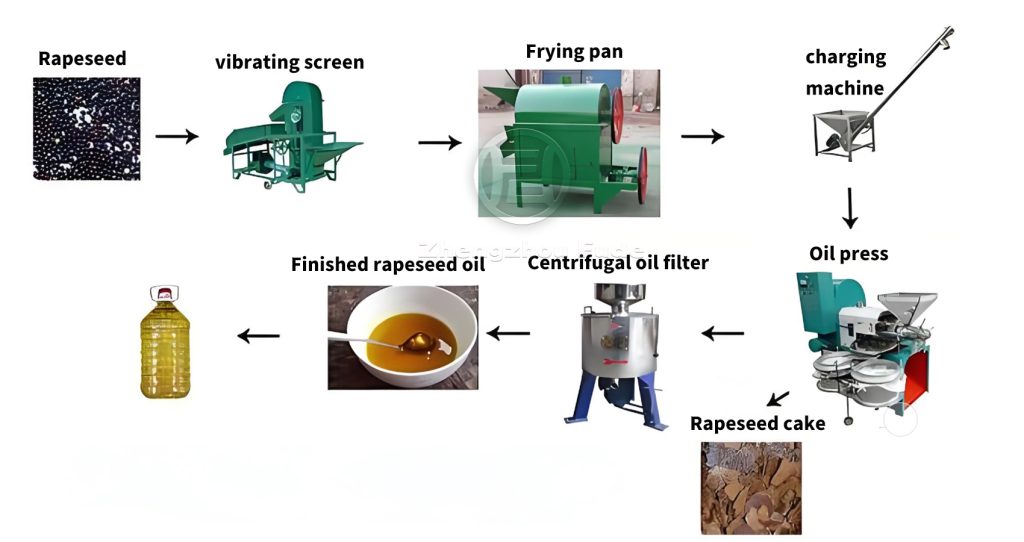

What are the complete sets of equipment for theoil press machine for home use production line?

- Pre processing equipment (such as shelling machines, screening machines, and frying machines) requires cleaning, stone removal, shelling, and crushing of raw materials before pressing, so there are many types of pre processing equipment.

- oil press for home use equipment. The commonly used equipment currently includes oil presses and leaching equipment. Oil press equipment (hydraulic oil press, screw oil press).

- Refining equipment (filtration equipment). Refining equipment is the main equipment that determines the quality level of edible oil. The main processes of refining equipment include five processes: degumming, deacidification, dehydration, decolorization, and deodorization. Depending on the type of oil, such as tea seed oil, rice bran oil, and other oils with high wax content, a set of dewaxing equipment needs to be configured after deodorization.

Specific process of spiral oil press

Working principle of oil press at home

The working principle of a mobile olive oil press is mainly based on the rotation of the screw shaft, which achieves the extraction of oil by continuously pushing and squeezing the material embryo in the pressing chamber. Specifically, the processed oil enters the pressing chamber from the hopper and is pushed forward by the rotating spiral shaft to move the material embryo forward. In the squeezing chamber, the material embryo is subjected to pressure and friction. As the root diameter of the squeezing screw gradually thickens and the pitch gradually decreases, the volume of the squeezing chamber space continuously shrinks, thereby exerting a squeezing effect on the material embryo. This continuous pushing and squeezing process causes the oil to be squeezed out of the material embryo and flow out through the gaps in the pressing chamber.

Spiral rod

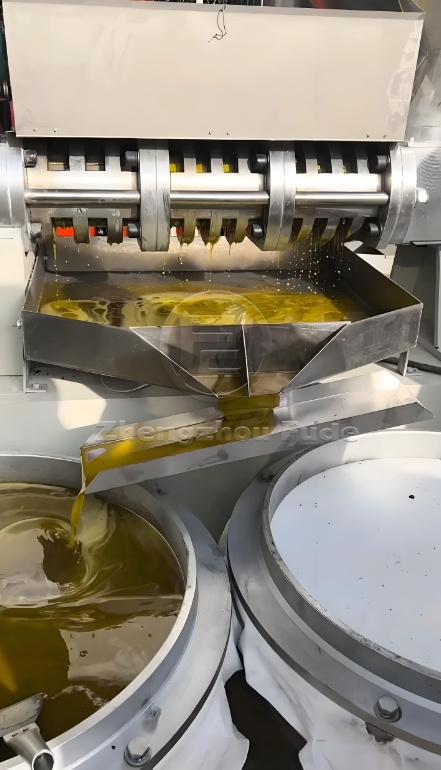

Oil filter barrel

Filter element

What are the advantages of lavender oil press?

olive oil press machine has a small footprint, high production efficiency, and advantages such as carefully selected materials, reasonable structure, beautiful appearance, reliable quality, simple operation, labor and electricity saving. It also has the advantages of automatic temperature control, one-time pressing, high oil yield, vacuum filtration, and high production efficiency.

Oil press equipped with filter barrels

castor oil press details are thoughtful and unique

- Double spiral reliable locking machine chamber

- The feeding port is widened and enlarged, making it easy to feed

- The overall framework is made of steel material, ensuring high and mild working performance

Double helix

Increase the feeding port

Steel frame

Reference map of extractable oil crops

It can easily press various materials such as olives, palm fruits, flaxseeds, coconuts, peanuts, sesame, corn germ, avocado, etc. For more materials, please consult customer service

Olive

Coconut

Flaxseed

Sesame

Palm fruit

Avocado

Peanut

Sunflower seeds

Good physical pressing effect and natural nutrition

The raw material nutrition is preserved intact, the taste is fragrant and not greasy, and it is suitable for commercial use. There are no chemical additives, ensuring the safety, hygiene, and pollution-free of the product. It is natural and nutritious, with a refreshing and pure taste.

Avocado oil

Sunflower oil

Olive oil

Sesame oil

Coconut oil

palm oil

peanut oil

Flaxseed oil

Customer cooperation cases

We have consulted and followed up with clients in the United States, the United Kingdom, South Korea, India, and other countries regarding the squeezing effect of different materials, and they have provided satisfactory answers.

American customer presses sesame oil

UK customer presses sunflower seed oil

Korean customers squeeze olive oil

Indian customers squeeze palm oil

Factory loading and departure site

What are the main factors that affect the oil extraction efficiency of an oil press?

- Raw material quality: The quality of raw materials directly affects the oil extraction effect. High quality peanut raw materials with high oil content and low impurities can improve oil yield.

- oil seed press performance: The performance of the oil press plays a crucial role in the oil pressing effect. An efficient oil press can more fully extract oil, improve oil yield and quality.

- Pressing process: Appropriate pressing process parameters, such as temperature, pressure, time, etc., can affect the oil extraction effect. Optimizing the process can improve oil extraction efficiency.

- Oil pretreatment: Proper pretreatment of oil, such as cleaning, shelling, crushing, etc., can improve the working efficiency of the oil press.

- Operator skills: The operator’s proficiency and skill level in operating the oil press can also have an impact on the oil extraction effect.

- Daily maintenance: Regular maintenance and upkeep of the oil press to ensure that the equipment is in good working condition, which is beneficial for improving the oil extraction efficiency.

- Environmental conditions: Factors such as temperature and humidity at the oil extraction site may also have a certain impact on the oil extraction effect.

In order to achieve better oil extraction results, it is necessary to comprehensively consider the above factors and take corresponding measures for optimization and improvement. At the same time, attention should be paid to safety production and equipment maintenance to ensure the smooth progress of the oil extraction process.

Oil Press Equipment and Oil Refining Machinery for Sale – Start Your Oil Press Business

Oil Press Equipment and Oil Refining Machinery for Sale – Start Your Oil Press Business