Fully automatic spiral oil press

Multifunctional spiral oil press

| Name | Spiral oil press | Purpose | Oil extraction |

The spiral oil press is mainly used as an oil press for individual home processing. This product belongs to a type of hydraulic fully automatic oil press, with a small output but simple and convenient. The main product now is the screw oil press. There are also spiral oil presses for cold pressing, which are relatively inexpensive but have a low oil yield.

Table of Contents

- Multifunctional spiral oil press

- Working video of screw oil press

- What is a screw oil press? Why is it called this name?

- The main working principle of the screw oil press

- Product technical parameters

- What are the advantages of products?

- Product details are thoughtful and unique

- Reference map of extractable oil crops

- Good physical pressing effect and natural nutrition

- Customer cooperation cases

- Factory loading and departure site

- How to choose the appropriate model of screw oil press?

Working video of screw oil press

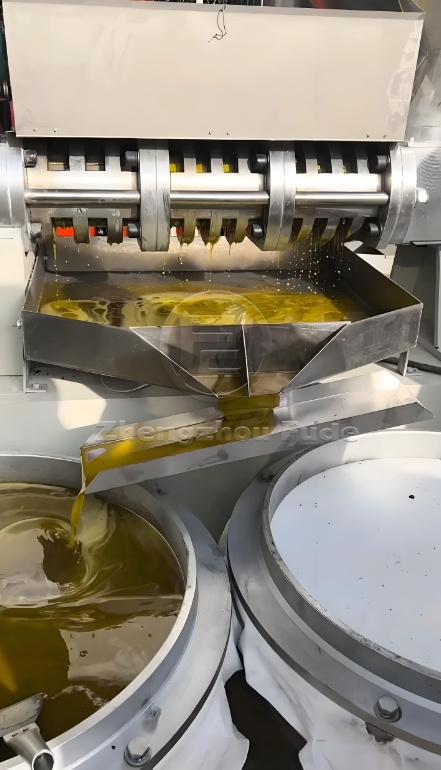

The oil extraction principle of a screw press mainly uses the oil extraction screw to rotate in the pressing chamber and squeeze out the oil material. After adding the oil at the feeding port, the screw rotates to push the oil into the pressing chamber, causing the oil to gradually deform and separate from the oil through strong pressure. Meanwhile, the squeezed oil residue is discharged from the machine through the oil residue outlet and stored in the waste residue storage tank.

What is a screw oil press? Why is it called this name?

The spiral oil press is based on the design principle of the oil press: there is a spiral shaft inside the oil press, which generates pressure through the rotation of the screw, forcing the raw material molecules to rupture, thereby achieving the purpose of oil extraction. So this type of oil press with a spiral shaft is called a spiral oil press. Spiral oil press is a common oil pressing equipment widely used in industries such as food, chemical, and pharmaceutical. It obtains oil by squeezing materials, which has the advantages of simple operation, low cost, and high oil content.

Oil press equipped with filter barrels

Single machine oil press

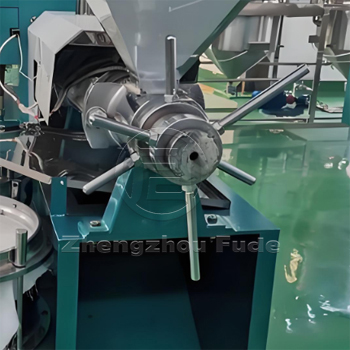

The main working principle of the screw oil press

The working principle of a screw oil press is mainly based on the rotation of the screw shaft, which achieves the extraction of oil by continuously pushing and squeezing the material embryo in the pressing chamber. Specifically, the processed oil enters the pressing chamber from the hopper and is pushed forward by the rotating spiral shaft to move the material embryo forward. In the squeezing chamber, the material embryo is subjected to pressure and friction. As the root diameter of the squeezing screw gradually thickens and the pitch gradually decreases, the volume of the squeezing chamber space continuously shrinks, thereby exerting a squeezing effect on the material embryo. This continuous pushing and squeezing process causes the oil to be squeezed out of the material embryo and flow out through the gaps in the pressing chamber.

Spiral rod

Oil filter barrel

Filter element

Product technical parameters

| Oil press model | 60 type | 70 type | 80 type | 100 type | 125 type | 150 type |

| Squeezing chamber diameter | 55mm | 65mm | 80mm | 101mm | 125mm | 150mm |

| Squeezing screw speed | 52r/min | 48r/min | 47r/min | 38r/min | 36r/min | 35r/min |

| Squeezing screw speed | 2.2kw | 3kw | 5.5kw | 7.5kw | 15kw | 18.5kw |

| Processing capacity | 30-60kg/h | 50-80kg/h | 65-130kg/h | 140-280kg/h | 300-400kg/h | 500-600kg/h |

| Overall weight | 220kg | 280kg | 780kg | 1100kg | 1280kg | 1420kg |

What are the advantages of products?

This oil press has a small footprint, high production efficiency, and advantages such as carefully selected materials, reasonable structure, beautiful appearance, reliable quality, simple operation, labor and electricity saving. It also has the advantages of automatic temperature control, one-time pressing, high oil yield, vacuum filtration, and high production efficiency.

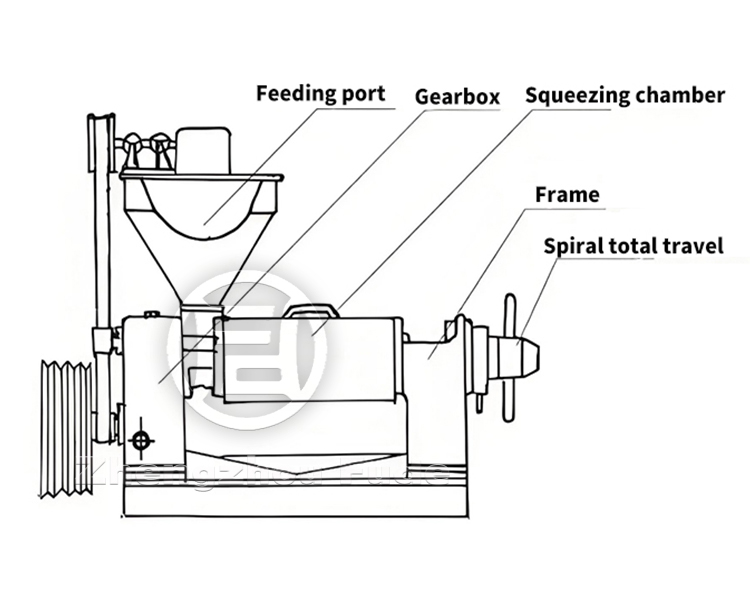

Oil press structure

Product details are thoughtful and unique

- Double spiral reliable locking machine chamber

- The feeding port is widened and enlarged, making it easy to feed

- The overall framework is made of steel material, ensuring high and mild working performance

Double helix

Increase the feeding port

Steel frame

Reference map of extractable oil crops

Easily squeeze multiple materials. Due to the large number of materials, it is not meaningful to list them. For more materials, please consult customer service

Soybean

White sesame

Olive kernel

Cottonseed

Pine kernel

Walnut kernel

Peanut

Black Sesame

Flaxseed

Tea seeds

Sunflower seeds

Rapeseed

Good physical pressing effect and natural nutrition

The raw material nutrition is preserved intact, the taste is fragrant and not greasy, and it is suitable for commercial use. There are no chemical additives, ensuring the safety, hygiene, and pollution-free of the product. It is natural and nutritious, with a refreshing and pure taste.

Peanut oil

Almond oil

Sunflower oil

Soybean oil

Rapeseed oil

Sesame oil

Corn oil

Flaxseed oil

Customer cooperation cases

We have consulted and followed up with clients in the United States, the United Kingdom, South Korea, India, and other countries regarding the squeezing effect of different materials, and they have provided satisfactory answers.

American customer presses sesame oil

UK customer presses sunflower seed oil

Korean customer presses corn oil

Indian customers pressing rapeseed

Factory loading and departure site

How to choose the appropriate model of screw oil press?

When choosing a screw oil press, the first thing to consider is the type of oil and the oil yield. Generally speaking, spiral oil presses are suitable for high oil crops such as rapeseed, sesame, and soybeans. Secondly, it is necessary to understand the structure, performance, and operation mode of the oil press. Choose an oil press with a stable structure, reliable performance, and convenient operation. In addition, the service life of the oil press and the convenience of maintenance should also be considered. In short, when choosing a screw oil press, factors such as the structure, performance, and usage scenario of the product need to be considered. By understanding these factors, one can better choose a suitable spiral oil press to improve the efficiency and quality of oil processing.

Related recommendations

-

Is olive oil produced by an oil press

85The process of extracting olive oil involves multiple steps such as picking, cleaning, crushing, pressing, separating, and filtering the olive fruit. It is recommended to use a Fude oil press to obtain high-quality olive oil products.

View details -

What is the difference between hot pressed and cold pressed sesame oil

33Cold pressing and hot pressing each have their own advantages and disadvantages, and you can choose according to your taste preferences and nutritional needs.

View details -

Soybean oil press

295The soybean oil press is a versatile machine that can be used to press various raw materials such as peanut,vegetable seeds, sunflower seeds, peanuts, flaxseeds, soybeans, camellia seeds, etc.

View details -

What are the advantages and disadvantages of hydraulic oil press

89As a commonly used oil extraction equipment, hydraulic oil press has its unique advantages and disadvantages. Let me introduce it to you In summary, hydraulic oil presses have their unique advantages and disadvantage...

View details

Oil Press Equipment and Oil Refining Machinery for Sale – Start Your Oil Press Business

Oil Press Equipment and Oil Refining Machinery for Sale – Start Your Oil Press Business

HelloPlease log in