How to find an affordable oil press for a small oil mill?

Choosing the right machine feels like a big task. Many options exist, and it’s hard to know where to start. Don’t worry, we build these machines, and we want to help you succeed. Let’s break down the key questions you should ask to find the perfect fit for your small oil mill.

My oil mill is just starting, what if my budget is limited?

Focus on essential features. A reliable single screw press machine often offers the best value for startups. Consider manual or semi-automatic models to reduce initial cost, and prioritize durability over complex features you may not need yet.

When you’re starting out, every penny counts. We understand that. At Zhengzhou Fude Machinery, we offer entry-level models designed for reliability and ease of use without breaking the bank. The key is to find a balance.

As a manufacturer (Zhengzhou Fude Machinery), offer factory-direct pricing, which helps keep your costs down by removing middlemen. We can help you select a basic, robust machine that gets the job done efficiently.

Screw press vs. hydraulic press, which is better for small yields?

You see different types of presses available. It’s confusing which technology – screw or hydraulic – works best when you’re not processing huge volumes. Choosing the wrong type could mean inefficiency.

For most small-scale, continuous operations processing common oilseeds like peanuts or soybeans, a screw press is generally more suitable and cost-effective. Hydraulic presses are better for batch processing or specific high-value seeds.

Let’s look at how these two main types of oil extraction equipment work for smaller operations. A screw press uses a rotating screw to continuously crush oilseeds and force the oil out through small openings in a barrel cage. A hydraulic press uses high pressure applied by a piston to squeeze oil out of a batch of material contained in a cylinder.

Understanding the Differences:

- Screw Press:

- Operation: Continuous feed and discharge. Good for steady production.

- Heat: Often involves friction heat, sometimes requires pre-heating (like our automatic temperature control models) for optimal yield with certain seeds.

- Throughput: Generally higher throughput for its size compared to hydraulic.

- Suitability: Excellent for common seeds like rapeseed, sunflower, soybean, peanut. Our range includes single and double screw presses.

- Hydraulic Press:

- Operation: Works in batches. Load material, press, unload cake, repeat.

- Heat: Often called “cold press” as minimal heat is generated by the process itself (though pre-treatment might involve heat). Good for heat-sensitive oils.

- Throughput: Lower continuous throughput. Labor-intensive for loading/unloading.

- Suitability: Ideal for high-value seeds where cold pressing is preferred (e.g., sesame, walnut, certain specialty oils) or when very low residual oil is critical.

For most startup oil mills aiming for consistent production of common oils, a screw press offers a better blend of efficiency, cost, and ease of use. We provide various screw press machine models tailored for different needs.

How much raw material do I need to process daily? How do I match the oil press capacity?

Matching machine capacity to your needs is crucial for efficiency. Start by estimating how much raw material (like sunflower seeds, peanuts, etc.) you plan to process each day or each shift. Consider your supply source, storage space, and market demand for your oil.

Estimating Your Needs:

- Source Availability: How much raw material can you reliably obtain per day or week?

- Market Demand: How much oil do you expect to sell daily or weekly? Work backward (considering yield rates) to estimate the required raw material input.

- Operational Plan: How many hours per day will you run the press?

For example, if you plan to process 500 kg of soybeans per day over an 8-hour shift, you need a machine capable of handling roughly 60-70 kg per hour.

Matching Machine Capacity:

- Rated Capacity: Manufacturers specify capacity, often in tons per 24 hours (T/24h) or kg per hour (kg/h). This is usually based on ideal conditions and specific materials (like soybeans or rapeseed).

- Actual Throughput: Real-world throughput can vary based on the type of oilseed, its condition (moisture content, cleanliness), and pre-treatment. Some seeds process slower than others.

- Buffer: Always choose a machine with a capacity slightly above your estimated daily need. This provides a buffer for busy days, potential future growth, or processing less dense materials. A machine running at 70-80% of its maximum rated capacity is often most efficient.

We offer a wide range of capacities, from small machines suitable for just a few hundred kgs per day up to equipment for complete oil mill plants. Tell us your estimated volume, and we can recommend the most suitable model.

Which types of oil presses are the easiest to operate and learn?

You might be new to oil pressing, or your staff may not have technical backgrounds. Complex machines are intimidating, raising concerns about operating errors and training time. You need something user-friendly.

Oil presses with automatic temperature control and simple interfaces are generally the easiest to operate. Look for models with clear labeling, straightforward controls (like PLC options), and easy cleaning procedures.

Ease of operation is a major factor, especially for small businesses where the owner might also be the main operator. You want a machine that doesn’t require extensive technical knowledge to run effectively day-to-day. At Fude Machinery, we focus on making our equipment accessible.

Features Enhancing Ease of Use:

- Automatic Temperature Control: This is a key feature. The machine automatically heats to the optimal pressing temperature for the selected oilseed and maintains it. This removes guesswork and ensures consistent oil quality. Many of our popular screw presses include this.

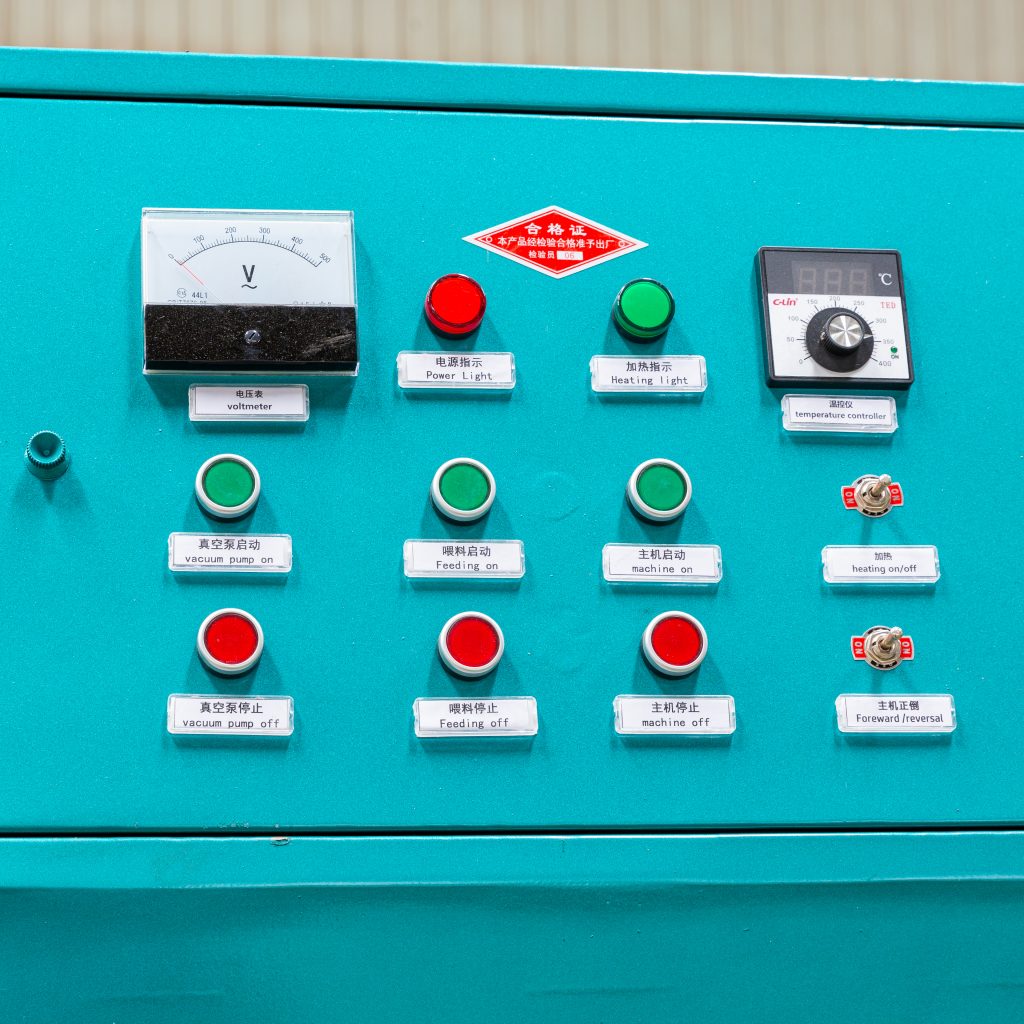

- Simple Control Panel: Look for clearly labeled buttons or a user-friendly touchscreen interface (PLC – Programmable Logic Controller). Avoid overly complex menus if simplicity is your goal.

- Easy Feeding: A well-designed hopper that allows for smooth, consistent feeding of raw materials is important.

- Straightforward Cleaning & Maintenance: How easy is it to access and clean the press cage and screw? Regular cleaning is vital. Machines designed for simpler disassembly and reassembly save time and effort.

- Clear Manuals & Support: Good documentation and accessible technical support (which we provide) are crucial for learning and troubleshooting.

Our automatic temperature control screw press machines are very popular with small mills precisely because they are easy to learn and operate, delivering consistent results with minimal fuss.

Apart from the machine price, are the ongoing maintenance costs high?

You know the purchase price is just the start. You’re worried about unexpected, high costs for spare parts, repairs, or energy consumption eating into your profits later on. Total cost matters.

Ongoing costs include electricity, wear parts (like the press screw and bars), and potential repairs. Choosing a durable machine from a reliable supplier with available spare parts minimizes long-term expenses. Factor these into your overall budget.

Investing in a quality machine from a reputable manufacturer like Zhengzhou Fude Machinery significantly reduces unexpected maintenance costs and downtime. We provide comprehensive after-sales support and spare parts to keep your operation running smoothly.

I want to improve oil yield, what key indicators should I look for when buying?

Maximizing the oil extracted from your raw materials directly impacts your profit. You’re concerned about leaving too much valuable oil behind in the cake. You need a machine that presses efficiently.

Look for machines with optimized screw design and press cage structure, precise temperature control capabilities, and a low specified residual oil rate in the cake (usually expressed as a percentage). Proper raw material pre-treatment is also crucial.

Getting the most oil out of every seed is the name of the game. Higher yield means more product to sell from the same amount of raw material. Machine design plays a huge role in this. Our R&D team continuously works on optimizing our press designs.

Key Factors Influencing Oil Yield:

- Screw Design: The shape, pitch, and depth of the screw threads determine how pressure builds along the barrel. Optimized designs ensure maximum, gradual pressure application. We tailor screw designs for different oilseeds.

- Press Cage Structure: The spacing between the bars of the press cage allows oil to escape while retaining the solid cake. The right spacing is crucial and can vary for different seeds.

- Pressure: The machine must be able to generate and sustain sufficient pressure to rupture the oil cells within the seed material.

- Temperature Control: For many seeds, pressing at the optimal temperature makes the oil flow more easily, increasing yield. Our automatic temperature control systems help achieve this consistently.

- Residual Oil Rate: Manufacturers may specify the typical percentage of oil left in the cake after pressing. Lower numbers are better. Ask for this data for the specific seeds you plan to process.

- Pre-treatment: This is critical! Cleaning, shelling (if needed), crushing/flaking, and cooking/conditioning the raw material properly before it enters the press significantly impacts yield. We also supply pre-treatment equipment.

Remember, the machine is only part of the equation. Even the best press needs properly prepared raw materials to achieve the highest yield. We can advise on both the press and the necessary pre-treatment equipment.

Does processing different oilseeds (like peanuts, soybeans, rapeseed) require special machine features?

You plan to process various types of oilseeds, maybe seasonally. You worry if one machine can handle everything well, or if you need different setups, complicating your operation.

Most modern screw presses can handle common oilseeds like peanuts, soybeans, and rapeseed with adjustments. However, optimal results might require slight changes in temperature, pressure, or screw configuration. Very hard or unusual seeds may need specialized machines.

Considerations for Specific Seeds:

| Oilseed Type | Key Considerations | Machine Adaptability | Fude Machinery Solutions |

|---|---|---|---|

| Peanuts | Often pressed with shells on (for feed cake) or shelled. Requires good pressure. | Most standard screw presses are suitable. | Wide range of suitable screw presses. |

| Soybeans | Benefit significantly from cracking, heating (cooking). | Standard screw press works, pre-treatment is key. | Offer presses and complete pre-treatment lines. |

| Rapeseed/Canola | Relatively small seeds, require proper cleaning. | Standard screw presses are well-suited. | Efficient screw presses available. |

| Sunflower Seeds | Often dehulled first for food-grade oil. | Standard screw presses work. | Presses and dehulling equipment offered. |

| Hard Seeds (e.g., Palm Kernel) | Require very high pressure and robust construction. | May need specialized, heavy-duty models. | We offer specific models designed for harder materials. |

| Soft/Specialty (e.g., Sesame) | Sometimes better suited for hydraulic press (cold press). | Screw press works, but hydraulic may be preferred. | We offer both screw and hydraulic presses. |

While a single, well-chosen screw press can be versatile, always discuss the specific range of oilseeds you intend to process with the manufacturer. We can confirm suitability or recommend specific configurations or necessary auxiliary equipment for optimal results across your materials.

Where can I buy reliable small oil presses with good after-sales support?

You’re ready to buy, but face many online sellers and local agents. You fear buying a low-quality machine, getting scammed, or ending up with no support if something goes wrong. You need a trustworthy source.

Investing in an oil press is a significant decision for your small mill. Choosing a reliable supplier like Zhengzhou Fude Machinery ensures you get not only a quality machine but also a partner committed to your success.

Conclusion

Choosing the right oil press involves matching budget, capacity, material needs, and seeking reliability and support. We hope this guide helps you make an informed decision for your small oil mill’s success.

Related recommendations

-

What is the difference between hydraulic oil press and screw oil press

322Zhengzhou Fude Machinery integrates research and development, manufacturing, and sales, deeply understands customer needs, recommends and answers equipment questions for customers, teaches operation techniques, and produces oil presses, refiners, ...

View details -

Difference between hydraulic oil press and screw oil press

24Static Pressure: The Hydraulic WayDynamic Force: The Screw Press MethodWhich Press Suits Which Oilseeds Best?Hydraulic Press: Simple Use, Specialized CareScrew Press: Automated Flow, Routine MaintenanceWhich Press Type Matches Different Production...

View details -

How to start a vegetable oil pressing business?

18What Are the Key Factors Affecting Vegetable Oil Yield?Can Crude Oil (Virgin Oil) Be Sold Directly, or Does It Need Refining?Refining Decision FactorsHow Much Startup Capital Is Roughly Needed, and How Can I Estimate ROI?Where Can I Find Reliable ...

View details -

How is sunflower oil processed?

9What Core Pressing and Refining Equipment Do I Need for a Sunflower Oil Plant?Must-Have Refining UnitsAuxiliary EquipmentFude's Complete SolutionsHow Can I Maximize Sunflower Seed Oil Yield and Ensure High Quality?Start with Good SeedsOptimize Pr...

View details

Oil Press Equipment and Oil Refining Machinery for Sale – Start Your Oil Press Business

Oil Press Equipment and Oil Refining Machinery for Sale – Start Your Oil Press Business

HelloPlease log in