How should I choose the raw material and the oil press?

Many plant parts containing oil can be pressed, including common seeds like peanuts and soybeans, and less common ones like grape seeds. Choosing the right oil press depends on the oilseed’s characteristics, required pre-treatment, processing scale, and desired oil quality.

Choosing correctly seems complex. But understanding the key factors makes it much simpler. Let’s break down what you need to know, based on our decades of experience at Zhengzhou Fude Machinery.

What Raw Materials Can Really Be Pressed Profitably?

Focus first on common, market-proven oilseeds like soybeans, peanuts, rapeseed, and sunflower seeds. While many niche materials can yield oil, their economic viability regarding collection, processing, and market demand is often uncertain for newcomers.

Thinking about pressing something unusual? Many factors decide if a material is worth pressing. It is not just about oil content.

My advice? Don’t jump at new or strange raw materials. Understand the full picture first – from collecting the seed to selling the oil and cake. For beginners, starting with well-known oilseeds is the safest path.

How Do Pre-treatment Details Affect Soybean, Peanut, and Rapeseed Oil Extraction?

Think you can just throw soybeans, peanuts, or rapeseeds into a press? Big mistake. Poor preparation leads to low yield and wasted potential, even with common seeds.

Proper pre-treatment like crushing, heating (cooking/roasting), and moisture adjustment is absolutely essential for soybeans, peanuts, and rapeseeds. Skipping or poorly managing these steps drastically reduces oil yield and can affect oil quality.

The devil is truly in the details when processing these popular oilseeds. Each has specific needs.

What Are the Hidden Pre-treatment Needs for Cottonseed, Sunflower Seed, and Sesame?

These seeds require specific pre-treatment beyond basic cleaning. Cottonseed needs gossypol removal and delinting/dehulling. Sunflower seeds need efficient dehulling. Sesame needs precise roasting for its characteristic flavor.

Ignoring these steps leads to major problems.

Do Hard-Shell or Specialty Oilseeds Require Dedicated Presses?

Dealing with tough materials like palm kernels or nuts like walnuts? You might wonder if your standard machine is enough, or if you need special equipment.

Yes, for high-volume, efficient processing of hard, high-oil materials like palm kernels or copra, specially designed oil presses are often necessary. For smaller batches of nuts, a hydraulic oil press can be a suitable alternative.

Buying a dedicated screw press for just one type of special oilseed is expensive. If you only process these occasionally, using a hydraulic press or adapting your existing screw press (accepting lower efficiency and potentially more wear) might be cheaper overall. However, for long-term, large-scale processing of these materials, a dedicated machine is usually the best investment.

If you genuinely process many different oilseeds, and each in small quantities, a well-regarded multi-functional press might be acceptable. Be prepared for the efficiency trade-offs.

How Do Operator Skill and Pre-treatment Impact Oil Yield and Quality?

You’ve got the right raw material and a good machine. Is that enough for top results? Not quite. Often overlooked factors like preparation and operation play a massive role.

High-quality pre-treatment and skilled operation are critical for maximizing oil yield and ensuring good oil quality. These factors can sometimes have a bigger impact than the raw material’s theoretical oil content or the press itself.

Success isn’t just about the seed or the steel. It’s about the entire process, including the human touch.

Raw Material is the Base

Of course, the starting material matters. Soybeans (~20% oil) will never yield as much as peanuts (~48%). Seed variety, origin, harvest year, and storage conditions all affect the actual oil content and initial quality (like acidity).

Pre-treatment is the Soul

This is where many gains are made or lost.

- Cleaning: Removing stones, dirt, metal is vital to protect machinery and ensure pure oil/cake.

- Sizing: Breaking or flaking seeds increases surface area for oil release.

- Cooking/Conditioning: This is crucial. Adjusting moisture and temperature breaks cell walls, reduces oil viscosity, deactivates harmful enzymes, and prepares proteins for efficient pressing.

- Veteran’s Secret: Excellent pre-treatment can boost oil yield by several percentage points from the same raw material compared to poor prep. It also greatly improves oil flavor, color, and stability (less gum, less phosphorus).

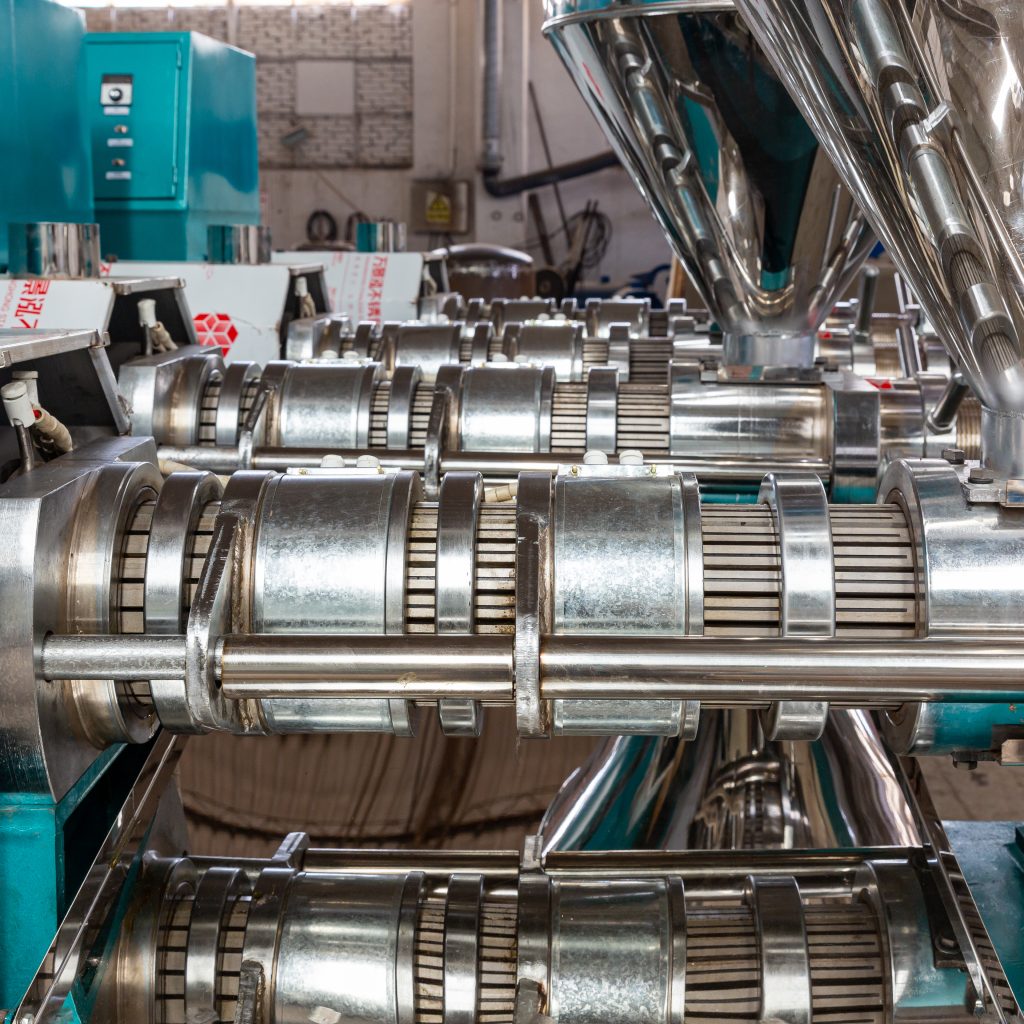

The Oil Press is the Heart

The machine’s type (screw press, hydraulic press), design (screw compression, chamber length, bar gaps), material quality (wear resistance), and settings (speed, temperature) determine how effectively oil is squeezed out.

Operator Experience is Key

Give the same machine to a novice and an expert, and the results can differ significantly. Experienced operators know how to judge and adjust temperature, moisture, feed rate, and cake thickness for optimal performance based on the specific material conditions that day.

What ‘Hidden’ Specs Matter When Choosing an Oil Press Model Besides Capacity?

Choosing an oil press based only on its “tons per day” capacity is a common mistake. Like buying a car based only on engine size, you miss crucial details that affect performance, reliability, and long-term cost.

Beyond capacity, critically evaluate the screw and chamber design, materials used (especially wear parts), gearbox quality, motor type, temperature control system, and the ease and cost of replacing wear parts. These ‘hidden’ specs determine real-world performance.

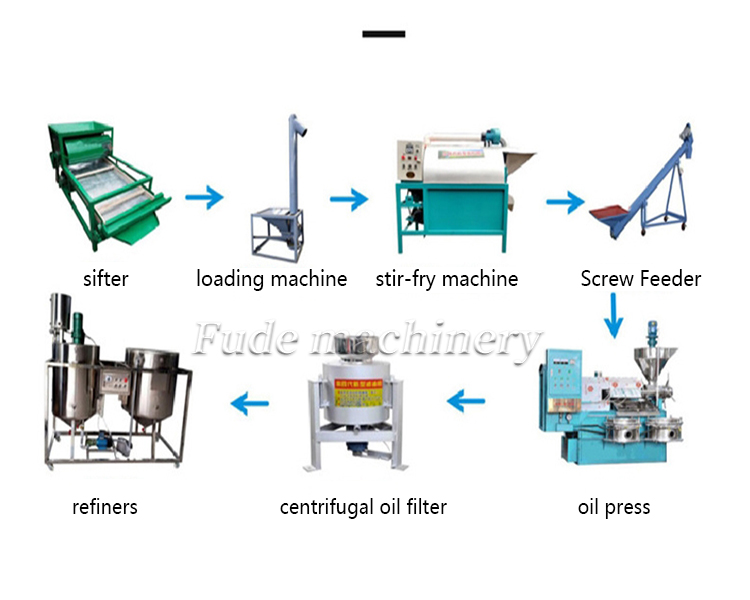

Why Is an Oil Press Just One Part of a Complete Processing Line?

Focused solely on buying the best oil press? That’s like planning a road trip by only thinking about the car’s engine. A successful oil mill plant needs a complete, integrated system.

An oil press is the heart, but a full oil processing line requires compatible equipment for cleaning, preparation (crushing/flaking/cooking), feeding, oil filtration, and cake handling to operate efficiently and produce quality oil.

Thinking systemically prevents bottlenecks and ensures smooth operation. Here’s what a typical line includes:

Input Stage (Preparation)

- Cleaning Equipment: Sieves (remove large/small trash), de-stoners, magnetic separators (remove metal). Often Underestimated: Poor cleaning wears machines faster and contaminates oil/cake.

- Preparation Machines: Specific to the oilseed – e.g., hullers (peanut, sunflower), crushers/flakers (soybean), etc.

- Conveying Equipment: Bucket elevators, screw conveyors, belt conveyors to move material between stages. Potential Problems: Mismatched capacity, blockages, cross-contamination.

Pre-treatment Core

- Cooker/Conditioner: The key place to adjust moisture and temperature. Various types exist (vertical, horizontal, steam-jacketed, direct steam). Selection Criteria: Match capacity, ensure accurate temperature control, uniform mixing, good steam sealing.

Pressing Core

- Oil Press(es): The main extraction unit(s). May need multiple in parallel or series for capacity.

- Feeder: Ensures a steady, controlled flow of prepared material into the press – vital for stable operation.

Output Stage (Handling)

- Oil Filtration Equipment: Crude oil needs cleaning. Options include filter presses (low cost, high labor), centrifugal filters (efficient, costlier), vacuum filters (good results). Choice Depends On: Level of filtration needed? Need de-gumming here?

- Cake Handling: Cake comes out hot and needs cooling (prevents fire risk). Then conveying, storage, or bagging. May need a cake breaker.

Easily Forgotten Auxiliaries

- Steam System: Boiler to provide steam for cooking.

- Electrical System: Total power load calculation, distribution panels, wiring.

- Storage: Raw material warehouse (dry, pest-proof), tanks for crude/refined oil, cake storage area.

- Structures: Operating platforms, support frames.

- Optional Refining: If producing standard edible oil, you’ll need a separate refinery equipment line (degumming, deacidification, bleaching, deodorizing).

Project Viewpoint: Designing a line requires matching capacities, ensuring smooth material flow, providing space for operation/maintenance, meeting safety standards, and considering environmental aspects (dust, noise). It needs holistic planning, not just buying individual machines.

Conclusion

Choosing the right oilseeds and oil extraction equipment involves understanding the whole picture – from raw material economics and preparation, to machine specifics and the complete processing line.

Related recommendations

-

What is the purpose of an oil press

374When the oil press is running, the processed material is carried as a hopper, and the oil enters the pressing chamber from the hopper. The spiral of the squeezed snail is pushed inward for pressing.

View details -

How to find an affordable oil press for a small oil mill?

12My oil mill is just starting, what if my budget is limited?Screw press vs. hydraulic press, which is better for small yields?Understanding the Differences:How much raw material do I need to process daily? How do I match the oil press capacity?Esti...

View details -

The difference between cold pressing and hot pressing of spiral oil press

292Spiral oil press is suitable for pressing various types of oil

View details -

How to start a vegetable oil pressing business?

17What Are the Key Factors Affecting Vegetable Oil Yield?Can Crude Oil (Virgin Oil) Be Sold Directly, or Does It Need Refining?Refining Decision FactorsHow Much Startup Capital Is Roughly Needed, and How Can I Estimate ROI?Where Can I Find Reliable ...

View details

Oil Press Equipment and Oil Refining Machinery for Sale – Start Your Oil Press Business

Oil Press Equipment and Oil Refining Machinery for Sale – Start Your Oil Press Business

HelloPlease log in