How to heat and press a spiral oil press machine

The process of heating and pressing in a spiral oil press is a complex and delicate operation aimed at improving the oil yield and quality of the oil. The following are the main steps and key points for heating and pressing a spiral oil press:

Preheating stage

- Preheating of the squeezing chamber: Before pressing oil, it is necessary to preheat the squeezing chamber. Preheating to the appropriate temperature (which depends on the type and characteristics of the oil) is a key step in ensuring the squeezing effect. Preheating helps soften the oil, reduce its viscosity, and make it easier for the oil to flow and exit during the pressing process.

- Heater function: The heater in the spiral oil press is the main equipment for preheating the pressing chamber. By the heating effect of the heater, the temperature inside the squeezing chamber gradually increases, preparing for the subsequent squeezing process.

Crushing stage

- Oil feed: After screening and frying (for hot pressing process), the oil enters the pressing chamber from the hopper. For the cold pressing process, it is directly pressed without the need for frying.

- Spiral shaft propulsion: The spiral shaft continuously rotates inside the squeezing chamber, driving the oil to move forward according to the reduction of lead or the gradual increase of root diameter. During this process, the volume of the squeezing chamber space continuously decreases, exerting a strong squeezing effect on the oil.

- Squeezing effect: As the volume of the squeezing chamber decreases, the pressure on the oil gradually increases. Friction occurs between oil particles and between oil and parts, generating heat. These heat and pressure work together to destroy the tissue cells of the oil, causing the oil to overflow from the oil line.

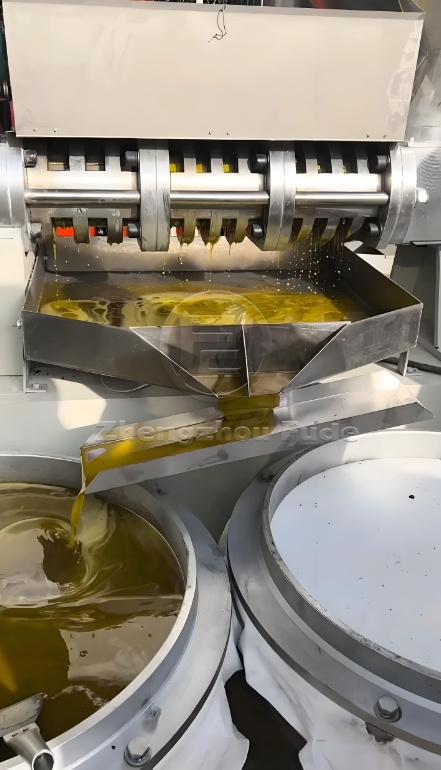

- Oil outflow and residue discharge: The squeezed oil is squeezed out from the gap of the squeezing cage, while the residue is pressed into a flaky cake and continuously discharged from the end of the squeezing shaft.

Temperature and moisture control

- Temperature control: During the squeezing process, it is necessary to closely monitor the temperature inside the squeezing chamber. Excessive or insufficient temperature may affect the squeezing effect and oil quality. Therefore, it is very important to accurately adjust the temperature through devices such as temperature controllers.

- Moisture control: For the cold pressing process, due to the fact that the oil has not been stir fried, the moisture content is relatively high. After pressing, it may be necessary to perform subsequent treatments such as boiling oil to remove excess moisture. For the hot pressing process, the moisture content of the oil is reduced through steps such as frying.

The heating and pressing process of a spiral oil press includes multiple steps such as preheating, pressing, temperature and moisture control. These links are interrelated and influence each other, jointly determining the squeezing effect and oil quality. Therefore, it is necessary to strictly follow the process requirements for operation and adjustment during the operation process to ensure that the squeezing effect reaches the best state.

Zhengzhou Fude Machinery Co., Ltd. integrates research and development, manufacturing, and sales. Our professional technical team has a deep understanding of customer needs, recommends and answers equipment questions for customers. If you want to know more, everyone has operational skills and produces agricultural product processing industries such as oil presses, refiners, dryers, and shellers. Please consult us.

Oil Press Equipment and Oil Refining Machinery for Sale – Start Your Oil Press Business

Oil Press Equipment and Oil Refining Machinery for Sale – Start Your Oil Press Business