What are the components of the spiral oil press body

The main body of the spiral oil press is composed of the following key parts:

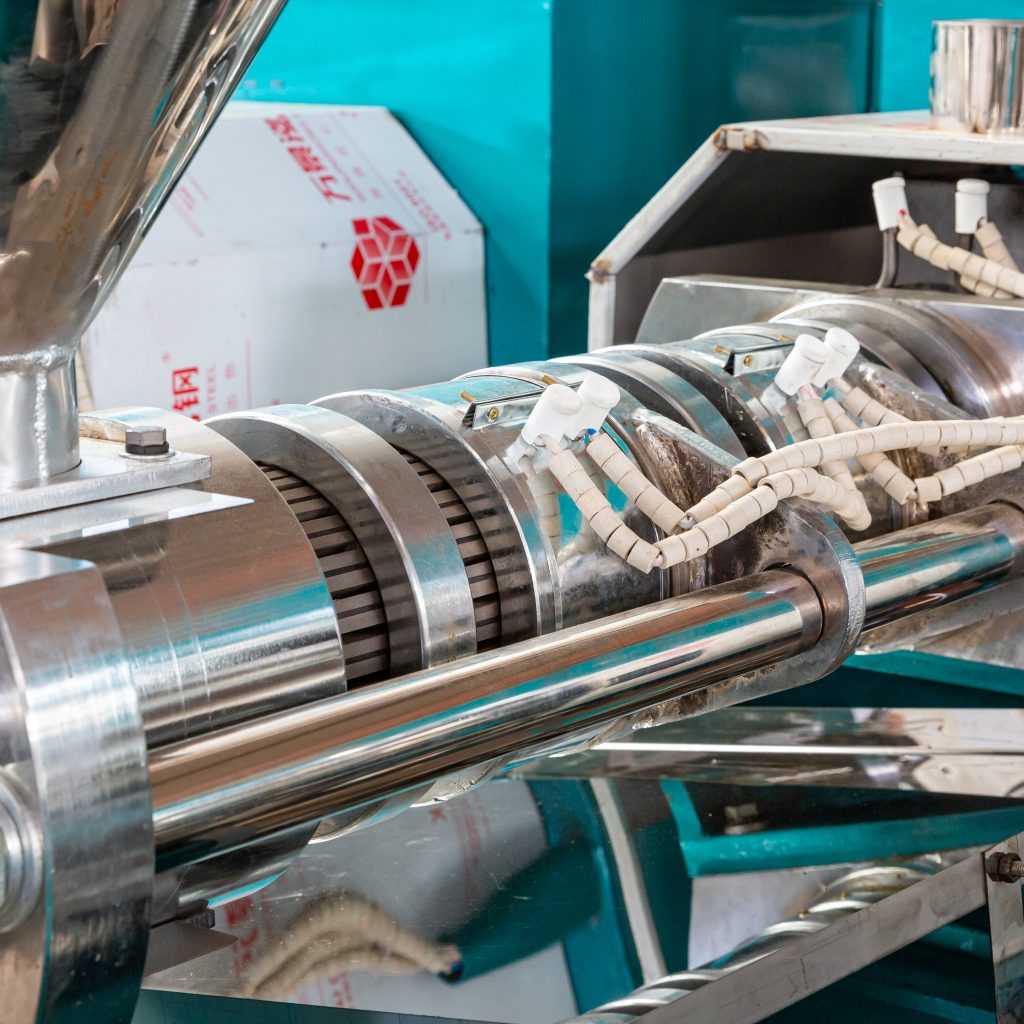

- Squeezing chamber: Squeezing chamber is the main operating part of a spiral oil press, consisting of a squeezing cage and a spiral shaft rotating inside the squeezing cage. The squeezing cage is usually a cylindrical structure, and the spiral shaft rotates inside it, driving the oil to be squeezed through its rotational motion.

- Spiral shaft: The spiral shaft is the core component inside the squeezing chamber, which drives the oil to move forward according to the reduction of lead or the gradual increase of root diameter through continuous rotation. During this process, the volume of the squeezing chamber space continuously decreases, resulting in a squeezing effect.

- Feeding hopper: The feeding hopper is located at the top or front of the spiral oil press and is used to feed the oil to be pressed into the press chamber. It is usually designed with an appropriate tilt angle and opening size to ensure that the oil can smoothly enter the squeezing chamber.

- Cake making mechanism: During the pressing process, the oil is compressed into cakes and discharged from the end of the pressing shaft. The cake making mechanism is used to adjust and control the thickness and shape of the cake blocks to ensure that they meet certain standards and requirements.

- Gearbox and motor: Gearbox and motor are the power sources of the spiral oil press. The motor transmits power to the screw shaft through the gearbox, allowing it to continuously rotate and drive the oil for pressing. The gearbox also plays a role in reducing speed and increasing torque to ensure that the screw shaft can rotate stably.

- Heating and pressing section: This section consists of a heater, pressing screws and strips, and machine assembly. The heater is used to heat the squeezing chamber to improve squeezing efficiency and oil yield. Snails and strips are used to press and squeeze oilseeds through their special structure and arrangement.

- Adjustment section: The adjustment section consists of adjustment screw, adjustment nut, sub handle, locking nut, etc. These components are used to adjust the position and angle of the screw shaft, as well as parameters such as pressure and temperature inside the press chamber, to meet the pressing needs of different types and qualities of oil.

- Vacuum oil filtration section (optional): Some high-end screw oil presses are also equipped with a vacuum oil filtration section. This part is composed of vacuum pumps, oil filter barrels, pipelines, etc., which are used to filter and purify the pressed oil to improve the quality and purity of the oil.

In summary, the main body of the spiral oil press is composed of key parts such as the press chamber, spiral shaft, feeding hopper, cake calibration mechanism, gearbox, and motor, which work together to complete the pressing of oil and the extraction of oil.

If you are interested in the agricultural product processing industry, please consult Zhengzhou Fude Machinery. We integrate research and development, manufacturing, and sales, and our products include agricultural product processing industries such as oil presses, refining machines, dryers, and shellers. We have rich industry experience and professional technical personnel to recommend equipment, develop comprehensive plans for single machines and production lines, and provide discounted prices for direct sales to manufacturers. We hope to receive your satisfaction.

Oil Press Equipment and Oil Refining Machinery for Sale – Start Your Oil Press Business

Oil Press Equipment and Oil Refining Machinery for Sale – Start Your Oil Press Business